Features and general description

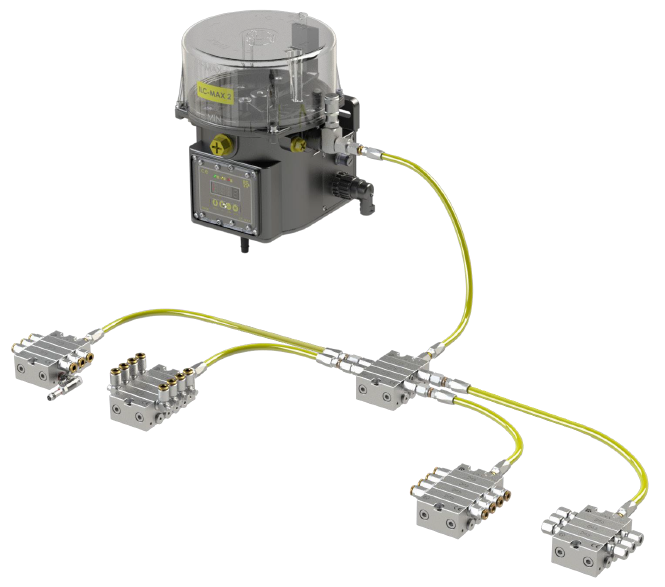

The DPX-N system distributes lubrication with a progressive movement of pistons, driving one another in an inter-dependent succession obtained by means of a single feed flow.

This system is highly qualified for dosing oil and grease for one or several support units. Each piston is in series with those preceding or with those following and the failure of one of them stops the sequence and therefore blocks the system.

This block also occurs when there is an external obstruction or an outlet that is not going to be used is closed. The application of just one element with visual or electric control is enough for an effective and complete control of the entire distribution system.

The pump flow rate is fractionable, by placing metering blocks in cascade. A block called master can feed one or more progressive distributors. The latter, in turn, can feed other distributors.

It is theoretically possible to continue but, for reasons related to compressibility and aeration of the lubricants, it is advisable not to exceed two cascades after the master. Malfunctions can occur if exceeded, especially when using low penetration index grease and minimum flow rates.

DPX-N metering device advantages:

- Absolute guarantee of delivering the pre-established amount of lubricant.

- Suited for use in systems requiring operating control.

- Absolute certainty of long life by means of a careful choice of materials and full control of processing.

- Possibility of checking operation by using visual and electric control devices.

- Designer has a large selection of available distributors and flow rat

| Technical data sheet | |

|---|---|

| Flow rate/stroke for single outlet (±10%) | 25 mm³ - 45 mm³ - 75 mm³ - 105 mm³ - 140 mm³ |

| Number of metering elements | From 3 to 12 |

| Operating pressure | From 15 to 300 bar |

| Operating temperature | From -20° C to 100° C |

| Distributor material | Galvanised steel Zi-Ni (free from Cr-V) / Stainless steel AISI 316L |

| Number of cycles | Max 250/min |

| Inlet seat | 1/8" BSP (M10x1 Special Execution) |

| Outlet seat | M10 x 1 |

| Fixing screws | M5 x 30 |

| Permitted lubricants (at the min. operating temp.) | Mineral oil 46 cSt - Max grease NLGI 2 |

| Control devices | Visual and electric indicating cycle and overpressure |

| Main lines | Pipes Ø 8-6 |

| Secondary lines | Pipes Ø 6-4 |

| Elements tightening torque | 9 Nm |

| O-rings | NBR or FPKM (on request) |

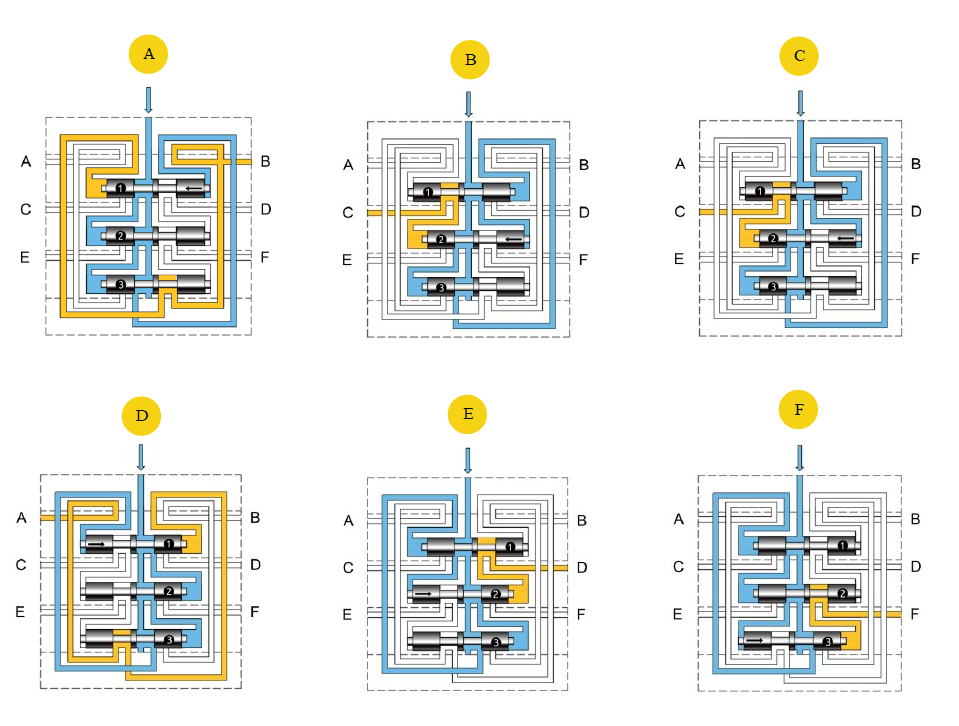

Operation

A. The pressurised lubricant flow (blue ) moves piston 1 to the left enabling dispensing (yellow) from outlet B.

B. When piston 1 has completed its stroke, the pressurised lubricant flow (blue) acts on piston 2. The volume of lubricant (yellow) is dispensed from outlet C.

C. When piston 2 has completed its stroke, the pressurised lubricant flow (blue) acts on piston 3. The volume of lubricant (yellow) is dispensed from outlet E.

D. When piston 3 has completed its stroke, the pressurised lubricant flow (blue) acts on piston 1. The volume of lubricant (yellow) is dispensed from outlet A.

E. When piston 1 has completed its stroke, the pressurised lubricant flow (blue) acts on piston 2. The volume of lubricant (yellow) is dispensed from outlet D.

F. When piston 2 has completed its stroke, the pressurised lubricant flow (blue) acts on piston 3. The volume of lubricant (yellow) is dispensed from outlet F. The progressive distributor is ready for a new cycle.

Outlets

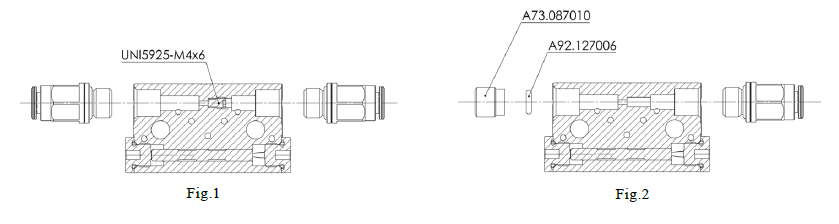

Each distributor piston is set up to feed 1 or 2 outlets.

When the separator grub screw is inserted (Fig.1) lubricant is dispensed in both outlets. When the grub screw is not inserted (Fig.2) lubricant is only dispensed from one outlet with a double flow rate.

When it is necessary to close an outlet thought to be used, remove the grub screw (UNI5925-M4X6) making sure to insert the closing plug (A73.087010 + A92.127006) in the outlet no longer used.

The same procedure is valid when, on the contrary, the amount of outlets must be increased. You must remove the closing plug and insert the separator grub screw. Distributors are normally supplied with the separator grub screw inserted and two side outlets open.

Important It is not possible to close both outlets relative to a single piston. All of the operations indicated above must be performed in a perfectly clean environment.

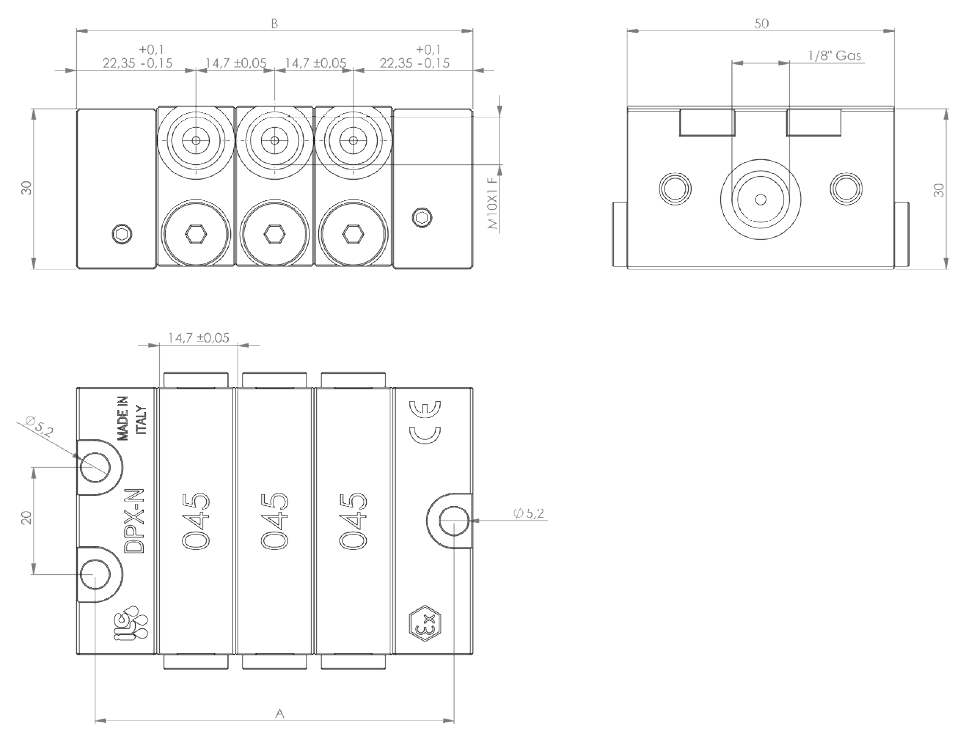

Overall dimensions

Tolerance ±0.05 mm for a single element. It is advisable to make the third fixing hole for mounting.

| Outlets | A [mm] | B [mm] |

|---|---|---|

| 6 | 67.1 | 74.1 |

| 8 | 81.8 | 88.8 |

| 10 | 96.5 | 103.5 |

| 12 | 111.2 | 118.2 |

| 14 | 125.9 | 132.9 |

| 16 | 140.6 | 147.6 |

| 18 | 155.3 | 162.3 |

| 20 | 170 | 177 |

| 22 | 184.7 | 191.7 |

| 24 | 199.4 | 206.4 |

ILC Lube: Supplier of Advanced Lubrication Systems for Various Industries

ILC Lube is a leading manufacturer of lubrication systems and equipment for diverse industries. The company offers a comprehensive range of lubrication systems, including progressive lubrication systems, metering systems, single and multiple metering valves, and manual lubrication systems. ILC Lube is known for its high-quality, custom-made lubrication systems and has built a global reputation for quality, reliability, and durability. Their lubrication systems are used in various industries, including metal, paper, food, automotive, and machine construction.

ILC Lube has a passion for innovation and is constantly working on the development of new and improved lubrication systems and technologies. By using ILC Lube lubrication systems, companies can enhance the performance and lifespan of their machines, reduce maintenance costs, and increase productivity.

Tailored Lubrication System Advice: We Help You Make the Right Choice

As lubrication specialists, we understand that each type of machine is unique and that operational conditions, such as ambient temperature and location, influence the selection of the most suitable lubrication method. If you need assistance in finding the ideal solution that meets your specific lubrication needs, we are ready to provide you with excellent advice. We offer solutions with an optimal price-performance ratio and would be happy to visit you on-site to provide tailored recommendations. Don’t hesitate to contact us.

Discover Simalube: the perfect solution for automatic single-point lubrication – fully autonomous, operates without any external power source.

For a complete range and expert advice, visit Pomac Lub-Services