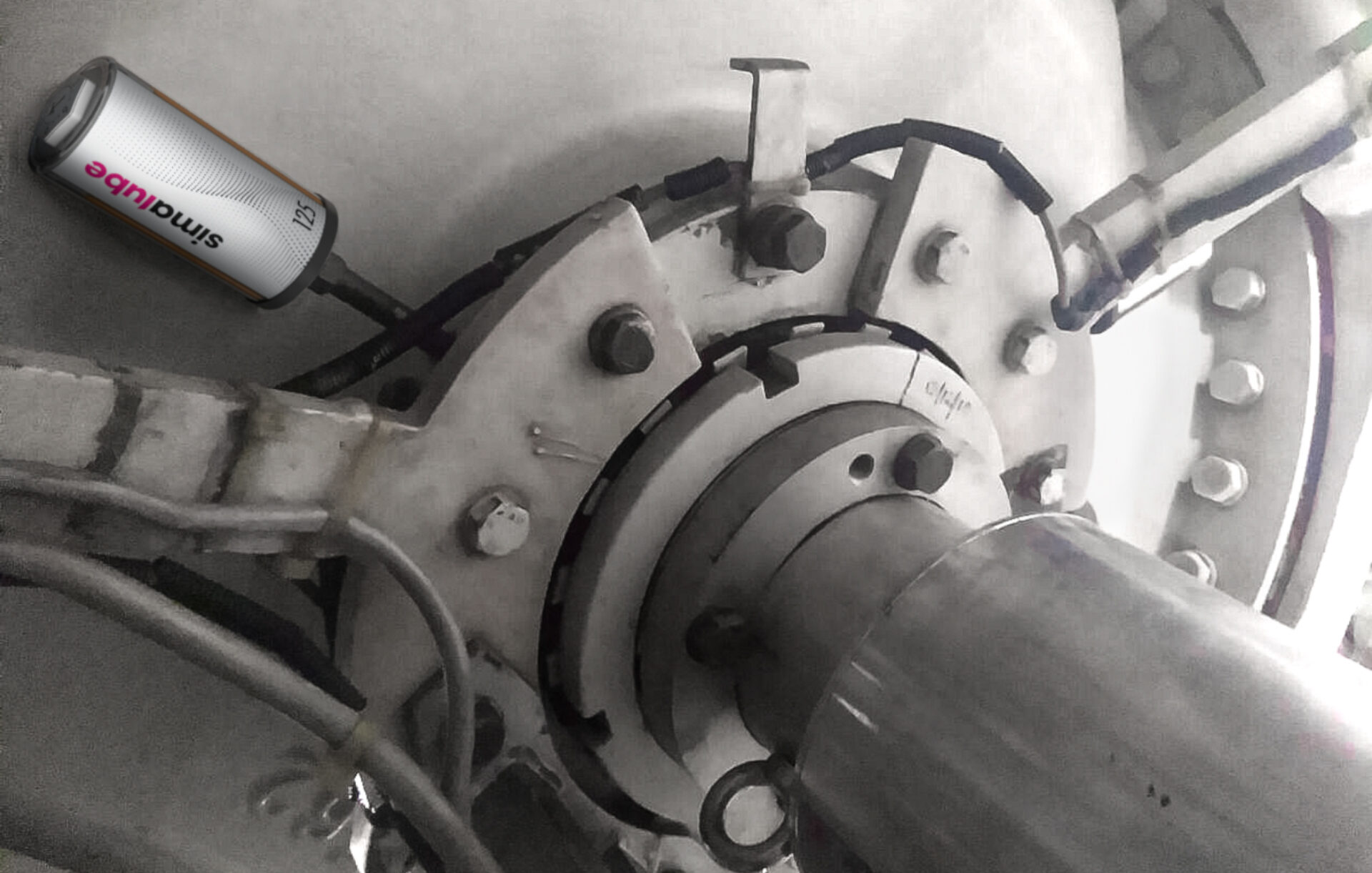

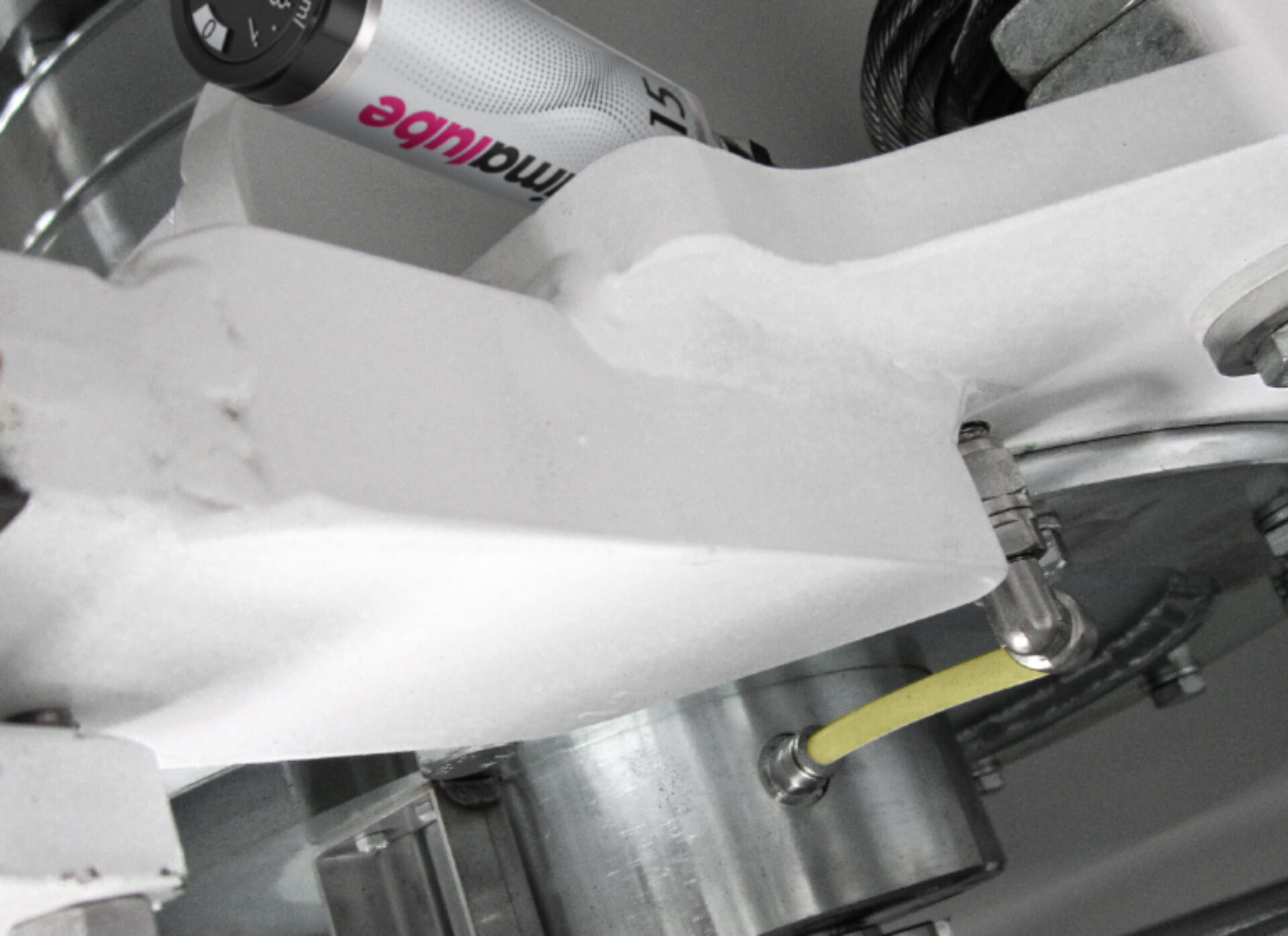

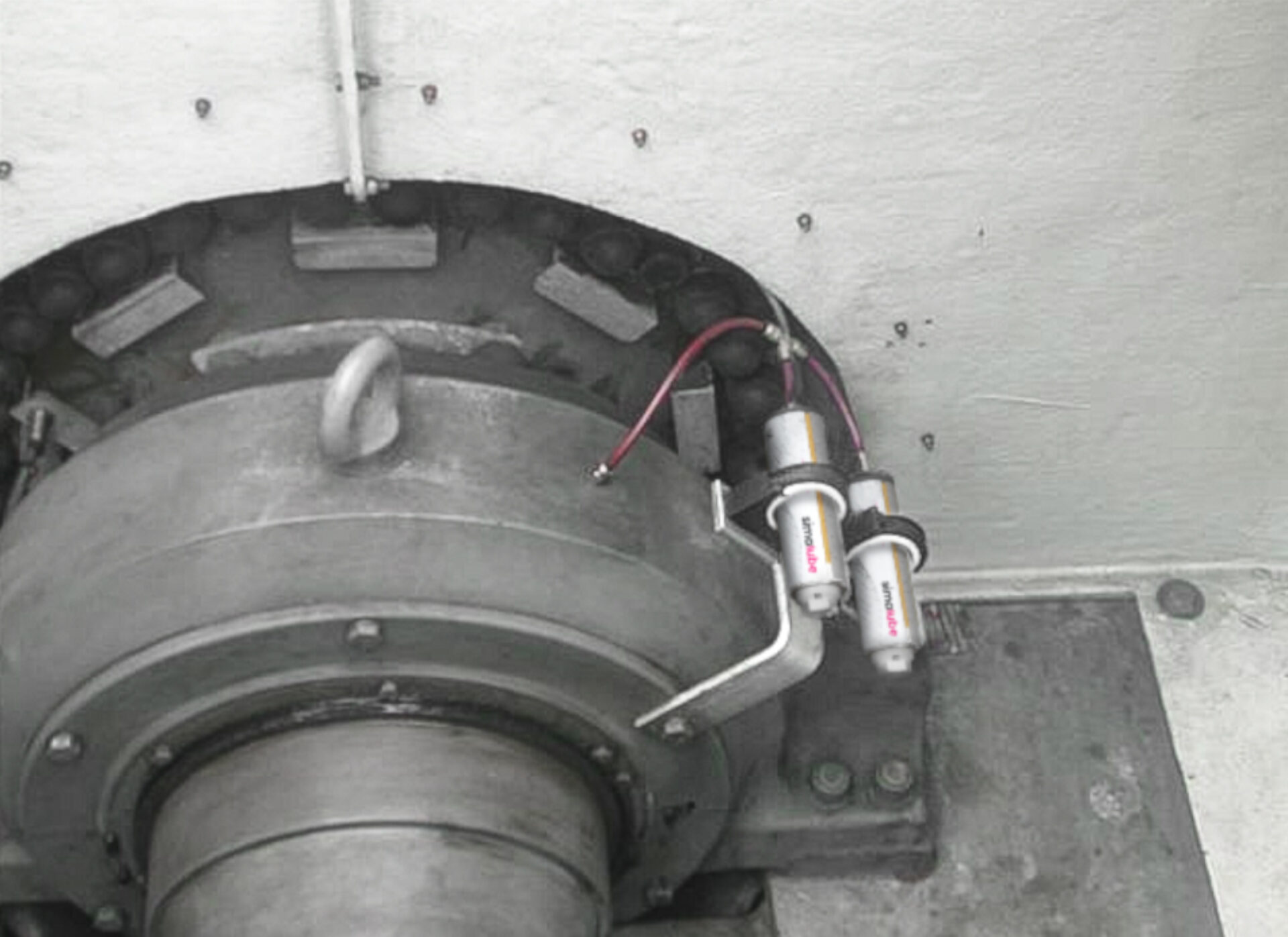

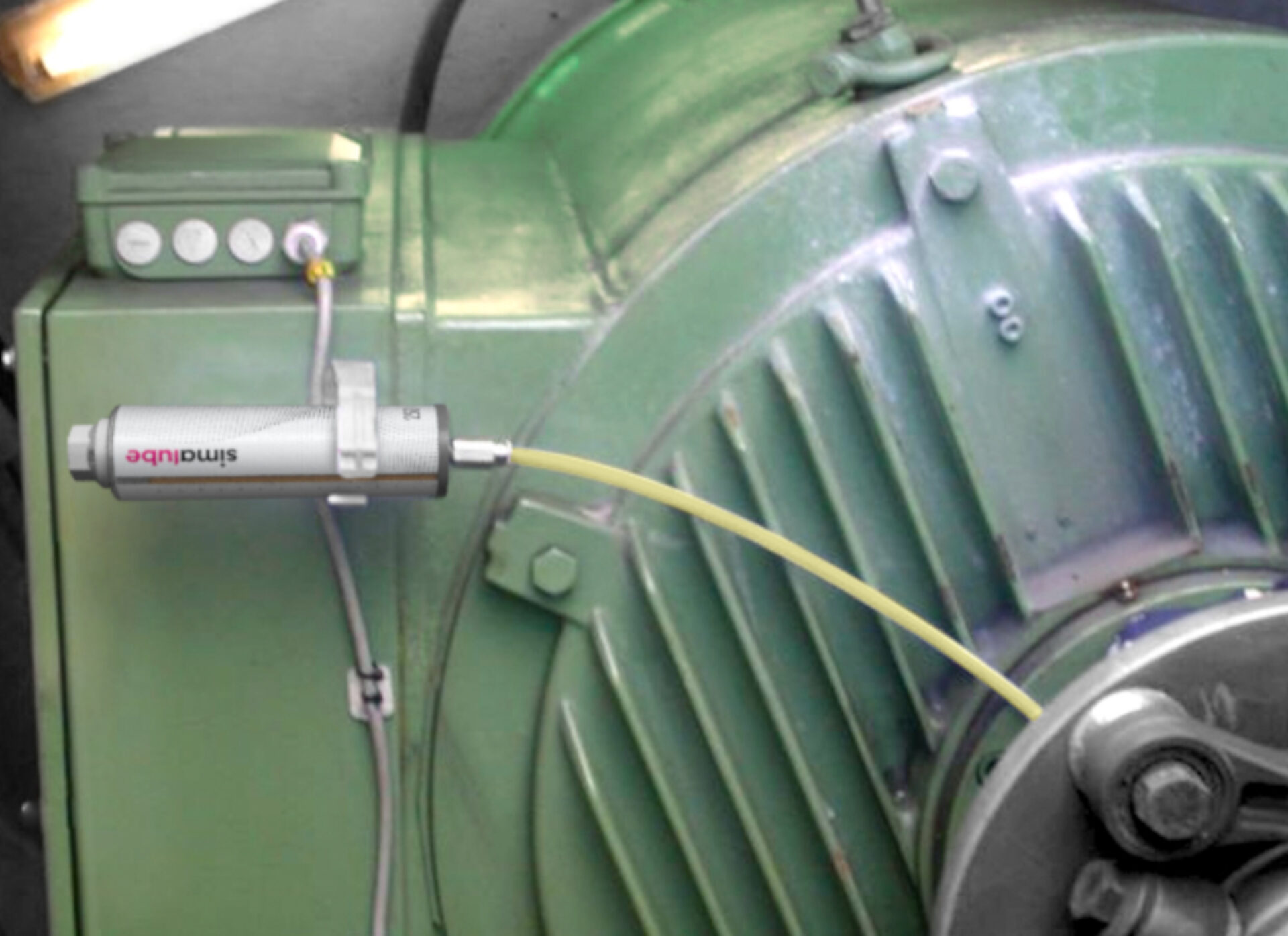

Every wind turbine has a multitude of lubrication points which have to be supplied at regular intervals. Since wind turbines are often located in remote locations, maintenance and the related lubrication is associated with a great deal of time and expense. Extreme temperature fluctuations, humidity and moisture are heavy burdens on every wind turbine. In order to prevent the resulting damage, optimum lubrication is indispensable. With the simalube lubrication system, wind farm operators can minimize the risk of downtime and also increase the efficiency of their wind turbines.

| Challenges | Solution |

|---|---|

| High demands on the availability of the systems | Simalube 60, 125 and 250 ml |

| Large seasonal temperature fluctuations | Installation direct, the lubricant is often supplied to the lubrication point via a lubrication pinion |

Areas of application and advantages

| Simalube areas of application for wind turbines | The benefits from automatic lubrication | Advantages of the Simalube lubrication system |

|---|---|---|

| Rotor blade adjustment | Increased operational safety | Reduction of service requirements and maintenance costs (manual lubrication is no longer necessary, thus there is less required labour and the time savings are great) |

| Rotor blade bearings | Reduced downtime | It is not necessary to shut down the machines during maintenance |

| Generator | Constant supply of hard to reach lubrication points | Longer service life of machines thanks to continuous and precise lubrication |

| Yaw drive | Less time spent on maintenance | Flexibility: The running time is adjustable from 1–12 months |

| Gearboxes | Reduction of wear and longer life of the components | Only one type of lubricator is needed per application. This allows a reduction of storage costs |

| Pitch adjustment (variable speed gear unit) | ||

| Main bearings |

ILC Lube: Supplier of Advanced Lubrication Systems for Various Industries

ILC Lube is a leading manufacturer of lubrication systems and equipment for diverse industries. The company offers a comprehensive range of lubrication systems, including progressive lubrication systems, metering systems, single and multiple metering valves, and manual lubrication systems. ILC Lube is known for its high-quality, custom-made lubrication systems and has built a global reputation for quality, reliability, and durability. Their lubrication systems are used in various industries, including metal, paper, food, automotive, and machine construction.

ILC Lube has a passion for innovation and is constantly working on the development of new and improved lubrication systems and technologies. By using ILC Lube lubrication systems, companies can enhance the performance and lifespan of their machines, reduce maintenance costs, and increase productivity.

Tailored Lubrication System Advice: We Help You Make the Right Choice

As lubrication specialists, we understand that each type of machine is unique and that operational conditions, such as ambient temperature and location, influence the selection of the most suitable lubrication method. If you need assistance in finding the ideal solution that meets your specific lubrication needs, we are ready to provide you with excellent advice. We offer solutions with an optimal price-performance ratio and would be happy to visit you on-site to provide tailored recommendations. Don’t hesitate to contact us.

Discover Simalube: the perfect solution for automatic single-point lubrication – fully autonomous, operates without any external power source.

For a complete range and expert advice, visit Pomac Lub-Services