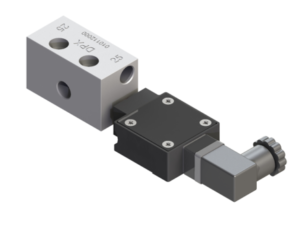

The micro switch controls the piston movement, monitoring the proper operation of the entire system.

At Ilclube.be, we offer high-quality DPX dosing elements with micro switch, essential for the optimal operation of automatic central lubrication systems. These components are designed to monitor piston movement and ensure correct lubricant dosing, contributing to the extended lifespan of your machines.

What is a DPX dosing element with micro switch?

A DPX dosing element is a crucial component of progressive lubrication systems. It consists of a start element, intermediate elements, and an end element, which together ensure uniform lubricant distribution across various points in your installation. The micro switch is integrated into the system and detects piston movement. This allows the system to signal when the piston has reached a specific point, crucial for cycle control and preventing over- or under-lubrication.

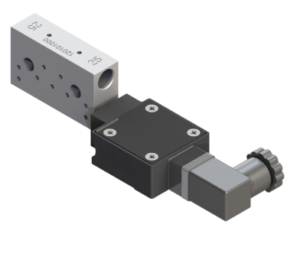

Advantages of using a micro switch

-

Reliable cycle control: The micro switch registers piston movements, enabling precise system monitoring.

-

Durability: Thanks to robust construction and high-quality materials, the dosing element withstands harsh conditions in industrial environments.

-

Easy integration: The micro switch allows simple connection to existing systems, making installation and maintenance efficient.

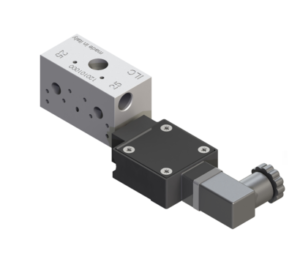

Applications across industries

DPX dosing elements with micro switch are widely used in industries such as metalworking, paper manufacturing, food processing, and machine construction. They are ideal for applications where precise and reliable lubrication is essential for maintaining continuous production processes.

ILC Lube: Supplier of Advanced Lubrication Systems for Various Industries

ILC Lube is a leading manufacturer of lubrication systems and equipment for diverse industries. The company offers a comprehensive range of lubrication systems, including progressive lubrication systems, metering systems, single and multiple metering valves, and manual lubrication systems. ILC Lube is known for its high-quality, custom-made lubrication systems and has built a global reputation for quality, reliability, and durability. Their lubrication systems are used in various industries, including metal, paper, food, automotive, and machine construction.

ILC Lube has a passion for innovation and is constantly working on the development of new and improved lubrication systems and technologies. By using ILC Lube lubrication systems, companies can enhance the performance and lifespan of their machines, reduce maintenance costs, and increase productivity.

Tailored Lubrication System Advice: We Help You Make the Right Choice

As lubrication specialists, we understand that each type of machine is unique and that operational conditions, such as ambient temperature and location, influence the selection of the most suitable lubrication method. If you need assistance in finding the ideal solution that meets your specific lubrication needs, we are ready to provide you with excellent advice. We offer solutions with an optimal price-performance ratio and would be happy to visit you on-site to provide tailored recommendations. Don’t hesitate to contact us.

Discover Simalube: the perfect solution for automatic single-point lubrication – fully autonomous, operates without any external power source.

For a complete range and expert advice, visit Pomac Lub-Services