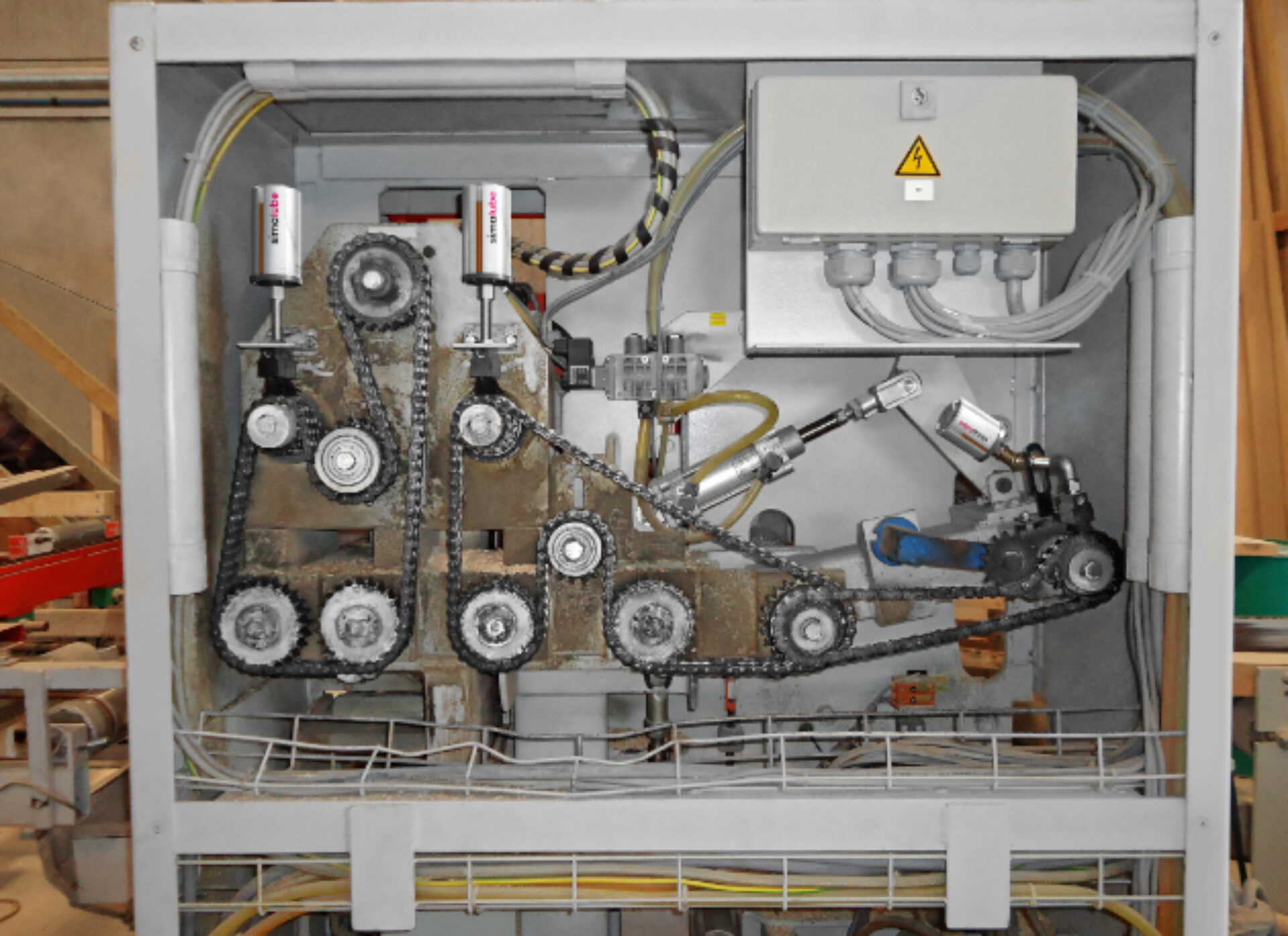

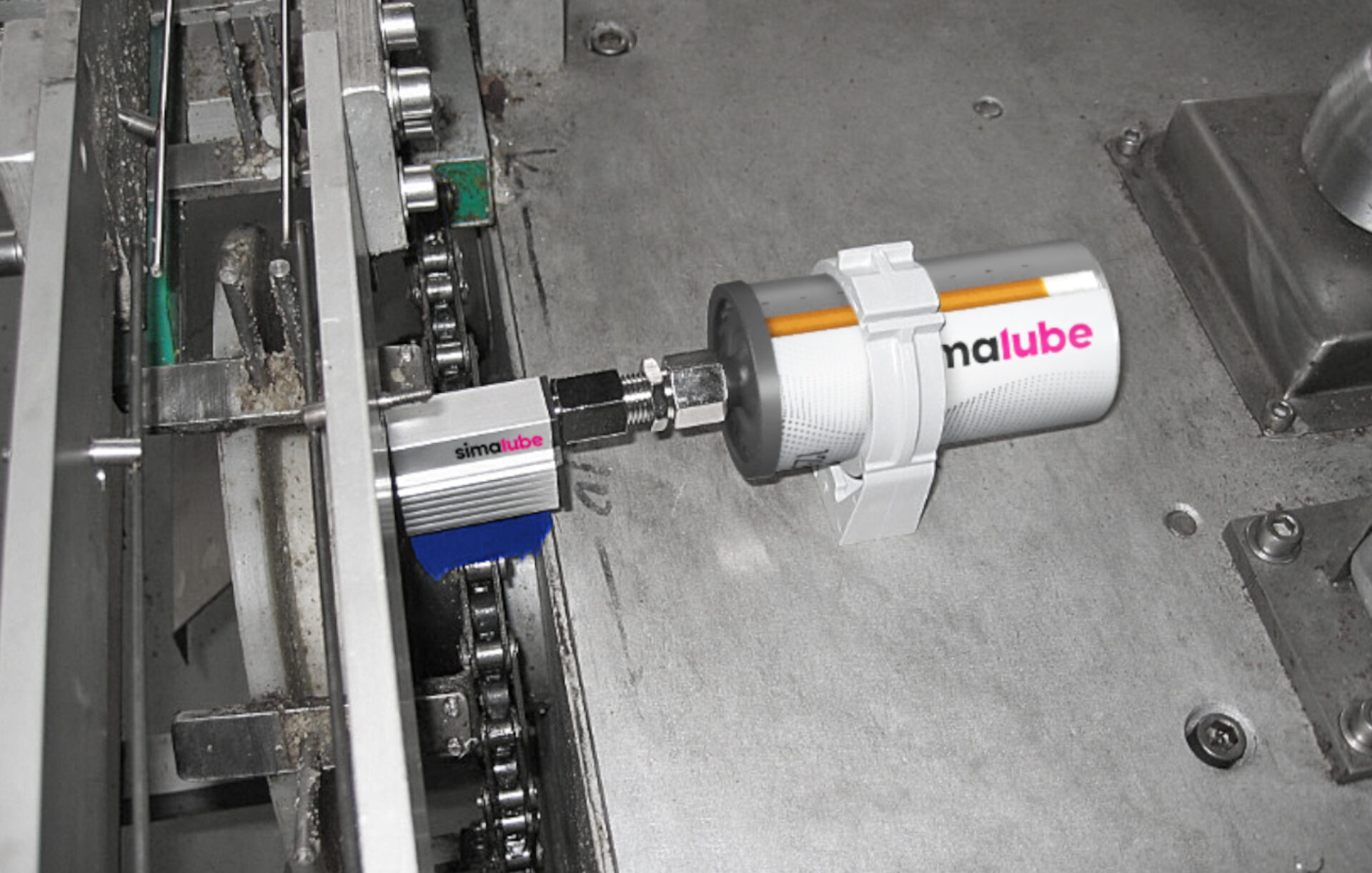

Simalube lubricates chains in any industrial environment, efficiently and reliably. Continuous lubrication with simalube prevents premature damage, reduces maintenance costs and increases functional reliability. In operating environments where there is a lot of dirt and dust, cleaning the chains is as important as their lubrication. By using simalube brushes, this cleaning is permanently ensured. Thanks to the comprehensive simalube accessory range, the lubricant dispenser can be optimally and professionally installed and adjusted for the corresponding chain applications in conjunction with different-sized brushes. The exact dosage and precise delivery signicantly reduce lubricant consumption.

| CHALLENGES | SOLUTION |

|---|---|

| Environment: pollution, high humidity - corrosion, high temperatures | The lubricant is applied to the chains via a brush |

| Technical: high loads | The dispenser can be mounted directly on the brush, the dispenser and brushes can also be connected by means of a hose line |

| Installation: little space, risk of collision, most different sizes and designs |

Areas of application and advantages

| simalube applications for typical chain uses | Advantages of the simalube lubrication system |

|---|---|

| Conveyor belts and chains | No oil drops on the floor, no contamination of the surrounding area |

| Escalators | Reduced servicing and maintenance costs: manual lubrication eliminated, meaning less inconvenience and massive time savings |

| High-speed chains | Rust, noisy operation and squeaky chains avoided through the use of simalube chain lubricant |

| Slat-band and roller chains | No need to turn off the machines for servicing |

| Hinges, slipways and slide rails | Chain service life considerably extended thanks to precise lubrication |

| Drying systems | Convenient solution for each type of chain due to individually deployable accessories |

| Chain drives | Once installed, the chains are reliably and continuously lubricated and cleaned |

| Transport facilities | |

| Washing facilities |

| simalube lubricants | simalube accessories |

|---|---|

| SL14 (chain oil, EP) | Flat brushes |

| SL15 (high-temp. chain oil, EP) | Flat brushes with lateral connection |

| SL18 (food oil, NSF H1) | Round brushes |

| SL19 (biodegradable chain oil) |

ILC Lube: Supplier of Advanced Lubrication Systems for Various Industries

ILC Lube is a leading manufacturer of lubrication systems and equipment for diverse industries. The company offers a comprehensive range of lubrication systems, including progressive lubrication systems, metering systems, single and multiple metering valves, and manual lubrication systems. ILC Lube is known for its high-quality, custom-made lubrication systems and has built a global reputation for quality, reliability, and durability. Their lubrication systems are used in various industries, including metal, paper, food, automotive, and machine construction.

ILC Lube has a passion for innovation and is constantly working on the development of new and improved lubrication systems and technologies. By using ILC Lube lubrication systems, companies can enhance the performance and lifespan of their machines, reduce maintenance costs, and increase productivity.

Tailored Lubrication System Advice: We Help You Make the Right Choice

As lubrication specialists, we understand that each type of machine is unique and that operational conditions, such as ambient temperature and location, influence the selection of the most suitable lubrication method. If you need assistance in finding the ideal solution that meets your specific lubrication needs, we are ready to provide you with excellent advice. We offer solutions with an optimal price-performance ratio and would be happy to visit you on-site to provide tailored recommendations. Don’t hesitate to contact us.

Discover Simalube: the perfect solution for automatic single-point lubrication – fully autonomous, operates without any external power source.

For a complete range and expert advice, visit Pomac Lub-Services