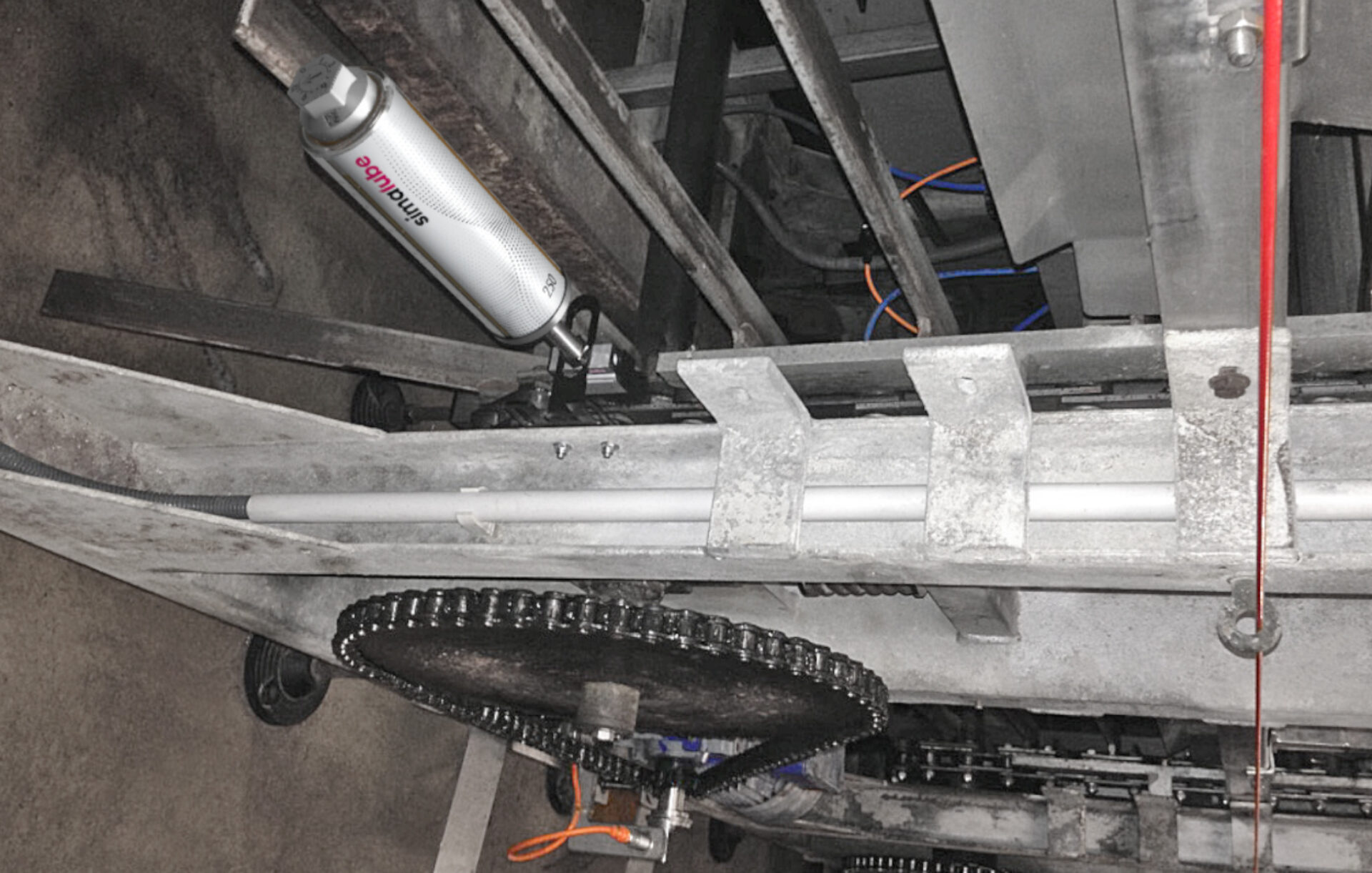

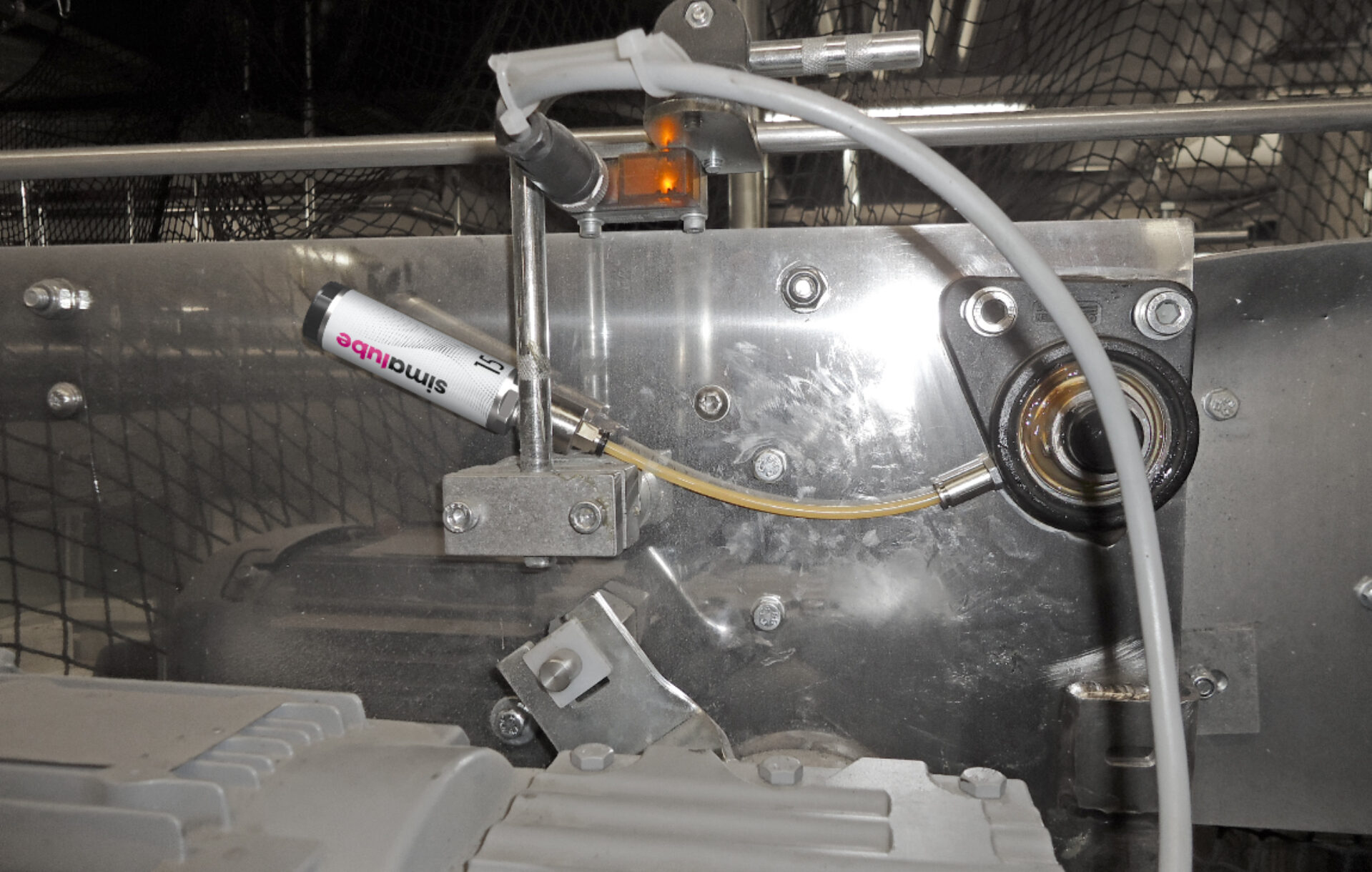

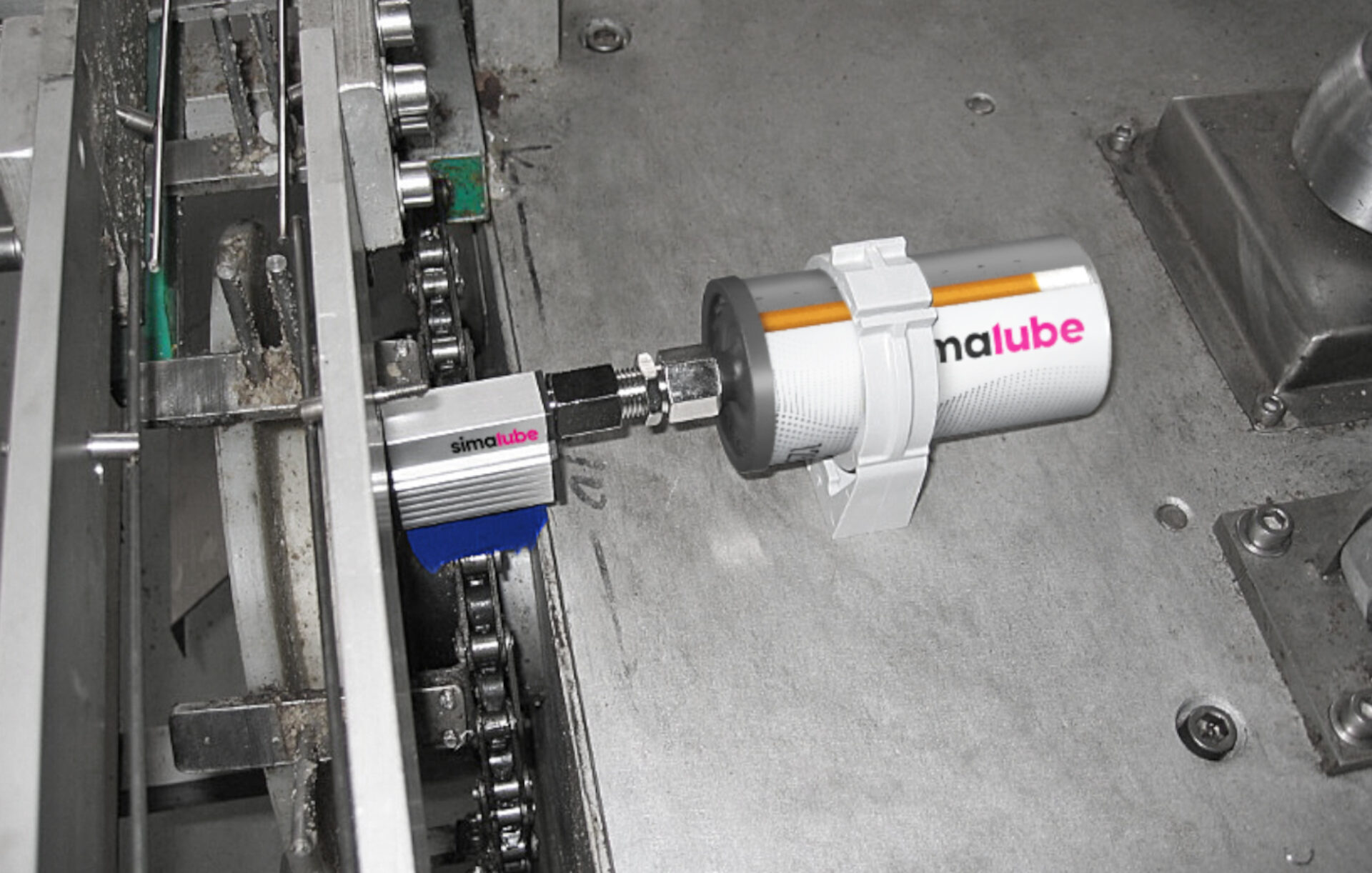

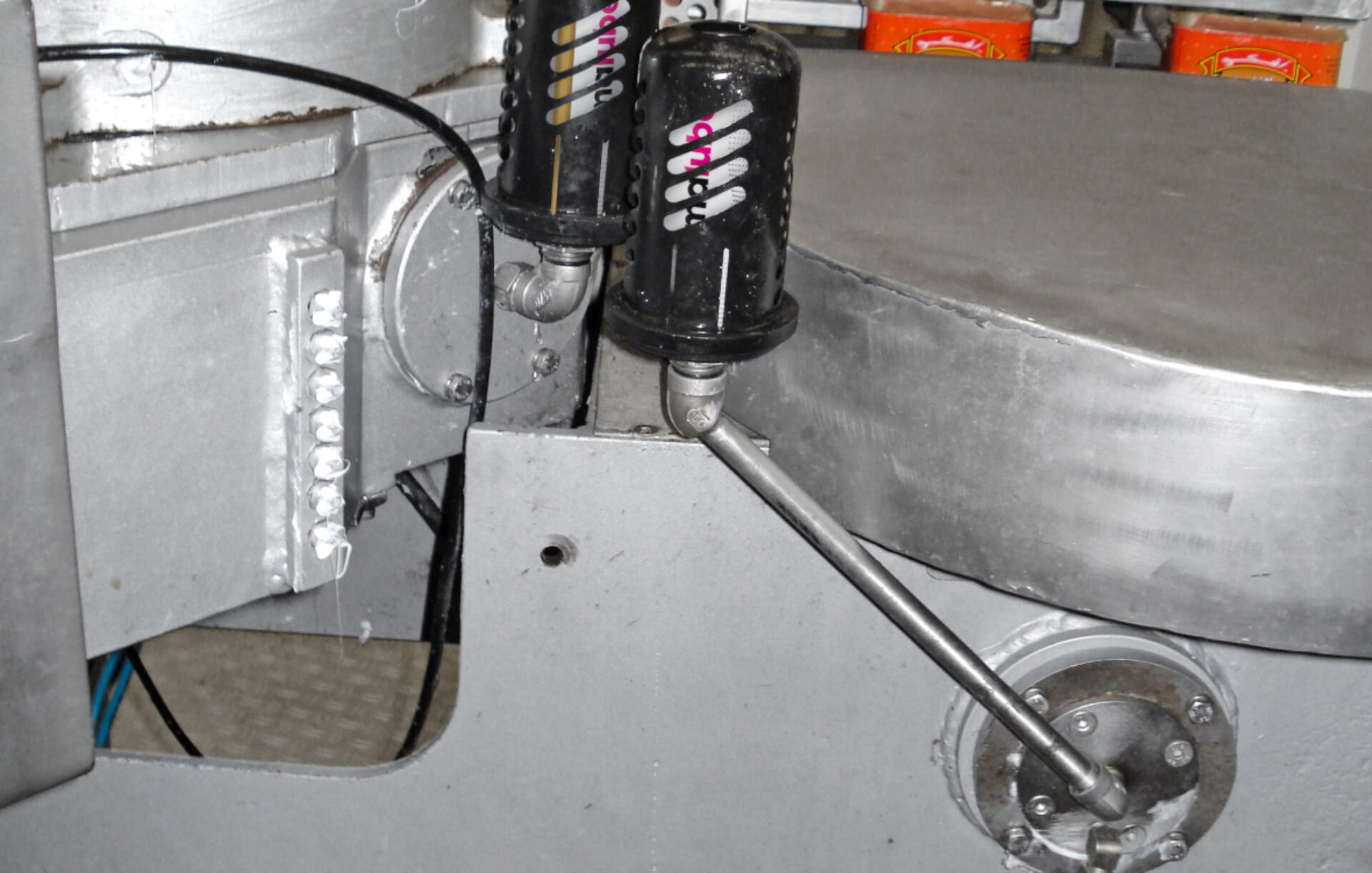

Machines and systems in the food industry must function perfectly even under extreme conditions of use. Dampness, contamination, high temperatures and high relative humidity stress the parts of the system and have a considerable adverse effect on the working life of bearings and chains. In most cases in the food industry, this involves mass production systems, where any downtime means high production losses. Even in modern beverage plants, chain or conveyor systems are in operation 24 hours a day and continuous lubrication extends their reliability and service life enormously.

| Challenges | Solution |

|---|---|

| High demands on the durability of the products | Simalube with H1 approved lubricants for the food industry |

| The use of approved special lubricants requires a flexible product | Special accessories for the food industry |

| Usage partly in dust explosion hazardous areas (ATEX) | Simalube lubricant dispensers are approved in all ATEX areas |

Areas of application and advantages

| Typical installations | Typical applications | Further benefits |

|---|---|---|

| Conveyor belts | Bearings | Increased operational safety |

| Palletizing systems | Chains | Reduced downtime |

| Presses | Guides | Constant supply of hard to reach lubrication points |

| Washing machines | Gears | Less time spent on maintenance |

| Packaging machines | Reduction of wear and longer life of the components | |

| Processing machines | ||

| Ventilators / Fans | ||

| Conveyor systems |

| Simalube applications in the food industry | Simalube applications in the beverage industry | Benefits from automatic lubrication with simalube |

|---|---|---|

| Preparation processes (peeling, grinding, pressing, cutting machines) | Filling machines | Reduction in servicing and maintenance: no more lubrication by hand, this results in enormous savings of time costs |

| Processing operations (washing units, cooling and freezing units) | Washing machines | It is not necessary to switch the machines off while they are being serviced |

| Filling and loading processes (conveyor systems, slicers, filling systems) | Belt conveyors | Longer service life of machines thanks to continuous and precise lubrication |

| Packing machines (packing, shrink-wrapping labelling) | Packaging and shrink-wrap machines | Flexibility: The running time is adjustable from 1–12 months |

| Palletizers | Presses | Only one type of lubricator is needed per application. This allows a reduction of storage costs |

| Refrigeration and freezer units | ||

| Label machines | ||

| Palletiser | ||

| Air conditioners (facility management) |

-

Technische informatie voor de voedingsindustrie

-

Technische informatie voor de drankenindustrie

-

Infomation technique pour lindustrie alimentaire

-

Information professionnelle pour lindustrie des boissons

-

Fachinformation für die Getränkeindustrie

-

Fachinformation für die Lebensmittelindustrie

-

Technical information for Beverage Industry

-

Technical information for the food industry

ILC Lube: Supplier of Advanced Lubrication Systems for Various Industries

ILC Lube is a leading manufacturer of lubrication systems and equipment for diverse industries. The company offers a comprehensive range of lubrication systems, including progressive lubrication systems, metering systems, single and multiple metering valves, and manual lubrication systems. ILC Lube is known for its high-quality, custom-made lubrication systems and has built a global reputation for quality, reliability, and durability. Their lubrication systems are used in various industries, including metal, paper, food, automotive, and machine construction.

ILC Lube has a passion for innovation and is constantly working on the development of new and improved lubrication systems and technologies. By using ILC Lube lubrication systems, companies can enhance the performance and lifespan of their machines, reduce maintenance costs, and increase productivity.

Tailored Lubrication System Advice: We Help You Make the Right Choice

As lubrication specialists, we understand that each type of machine is unique and that operational conditions, such as ambient temperature and location, influence the selection of the most suitable lubrication method. If you need assistance in finding the ideal solution that meets your specific lubrication needs, we are ready to provide you with excellent advice. We offer solutions with an optimal price-performance ratio and would be happy to visit you on-site to provide tailored recommendations. Don’t hesitate to contact us.

Discover Simalube: the perfect solution for automatic single-point lubrication – fully autonomous, operates without any external power source.

For a complete range and expert advice, visit Pomac Lub-Services