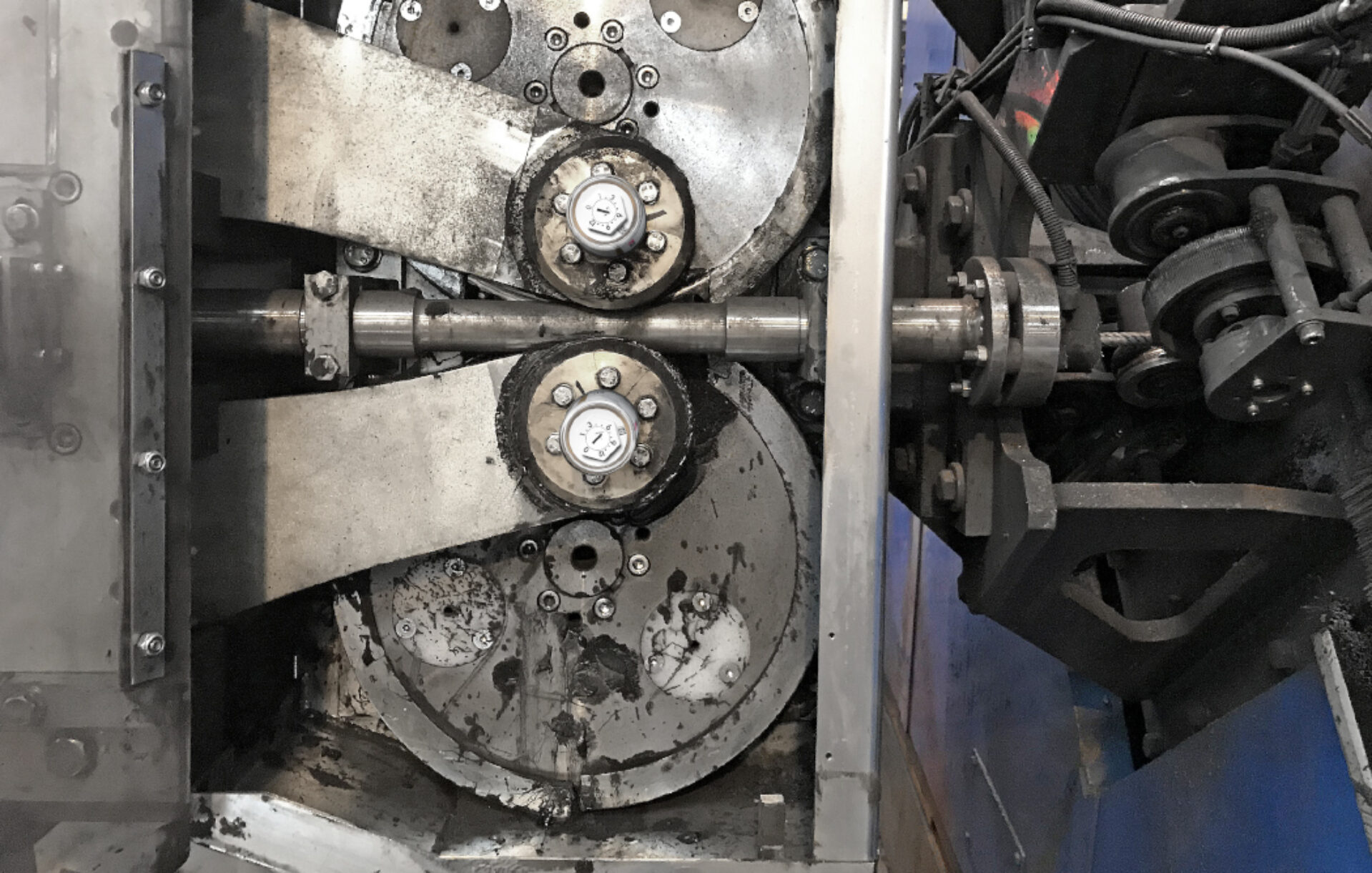

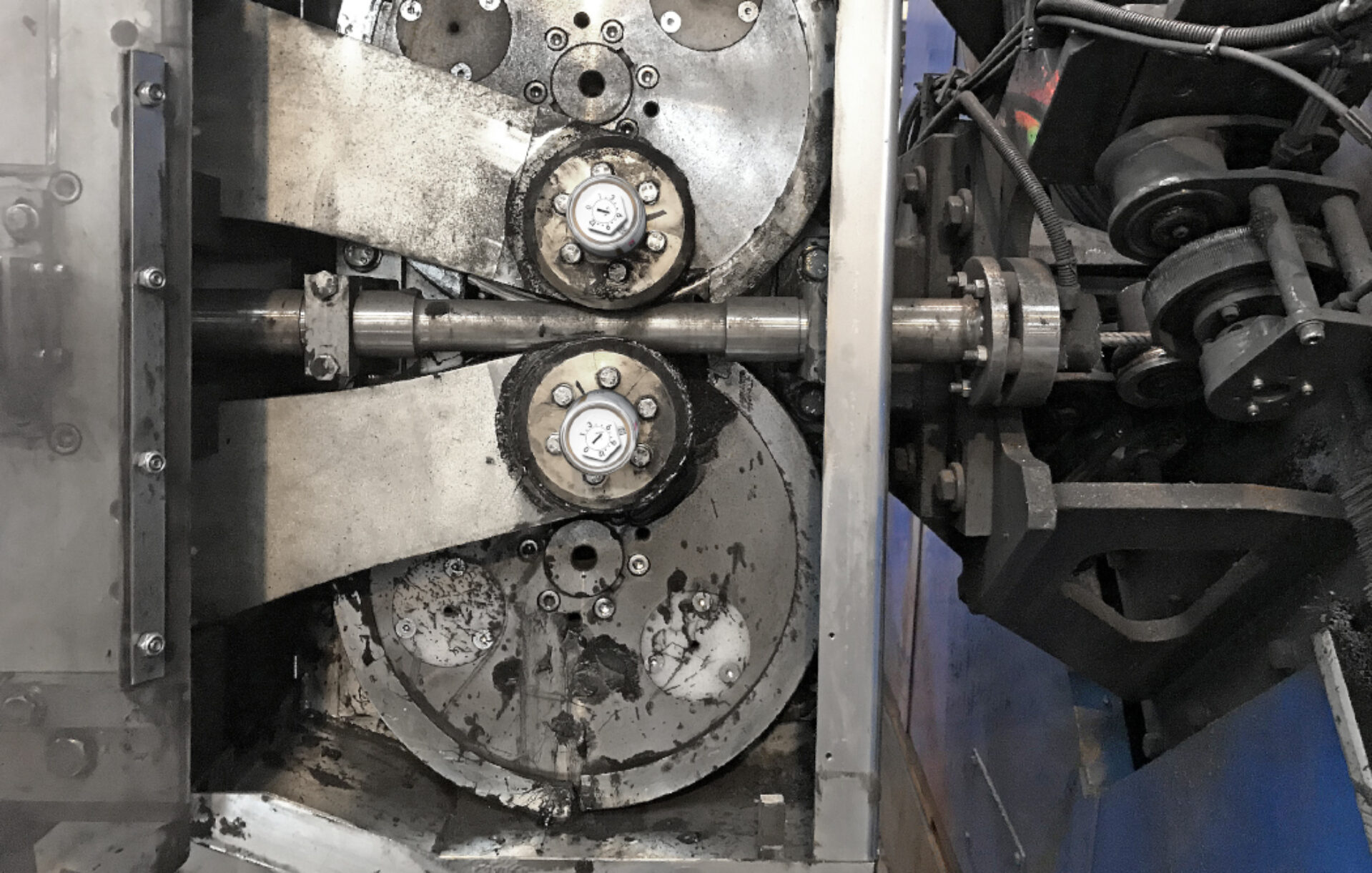

The severe working conditions in the steel industry are a challenge not only to the operators but also the machines in particular. Heat, dust, vapours and dirt stress the facilities and often bring them to their limits. Among other things, a continuous lubrication of the facilities is crucial to prevent the resulting machine failures.

| Challenges | Solution |

|---|---|

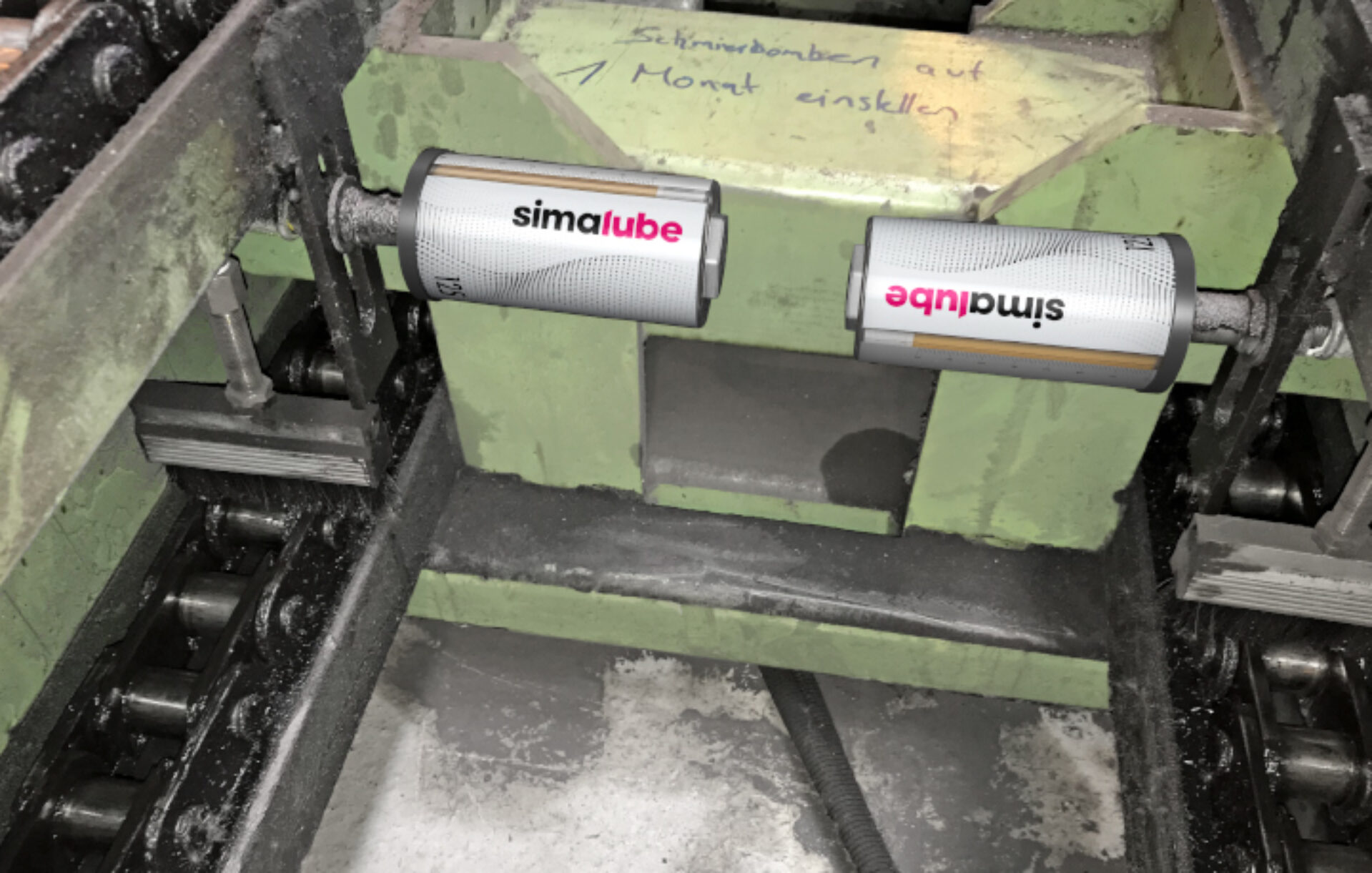

| Rough use | Simalube lubricators |

| Temperature fluctuations, risk of damage to the installations | Partial special accessories for tight spaces |

| High load on the systems | IMPULSE connect: Digital monitoring and configuration of the lubrication points via Bluetooth®. The lubrication points can be monitored from a distance of 20 m. The device can be used to increase the pressure up to 10 bar |

| High back pressure | Accessories and hose so that the dispensers can be mounted outside hazardous areas |

Areas of application and advantages

| Areas of application for Simalube in steel production processes | Plants/machines in steelworks | Simalube applications in steelworks |

|---|---|---|

| Coking facility | Conveyor systems | Bearings |

| Refining of pig iron | Fan units | Sliding rails |

| Sintering facility | Gearboxes/motors | Chains |

| Alloying of steel | Blower motors | Joints |

| Blast furnaces | Pumps | Toothed racks |

| Vacuum unit | Mixers | Arms and links |

| Desulphurization | Strainers | Pinions |

| Continuous casting facility | Motor bearings | Guide rollers |

| Removal of slag | Cranes | Gas valves |

| Ingot casting | Ovens | Couplings |

| Filling of the converter | Rollers | |

| Roll stands |

| Benefits from automatic lubrication | Advantages of simalube lubrication systems |

|---|---|

| Less downtime of the facilities | Reliability: Once installed, the lubrication points are reliably lubricated and never forgotten |

| Reduction of wear and longer service life of the components | The hermetically sealed system prevents contamination by dust and debris (IP68) |

| Increased operational safety since manual lubrication is not required | Reduction of service requirements and maintenance costs: Manual lubrication is no longer necessary meaning fewer disruptions and a huge saving of time |

| Long-term supply of lubrication points that are heard to reach | Longer service life of machines thanks to continuous and accurate lubrication |

| Less time required for maintenance | Flexibility: The running time is adjustable from 1–12 months |

| No need to shut down the machines during maintenance | |

| Installation is possible even in very narrow spaces |

ILC Lube: Supplier of Advanced Lubrication Systems for Various Industries

ILC Lube is a leading manufacturer of lubrication systems and equipment for diverse industries. The company offers a comprehensive range of lubrication systems, including progressive lubrication systems, metering systems, single and multiple metering valves, and manual lubrication systems. ILC Lube is known for its high-quality, custom-made lubrication systems and has built a global reputation for quality, reliability, and durability. Their lubrication systems are used in various industries, including metal, paper, food, automotive, and machine construction.

ILC Lube has a passion for innovation and is constantly working on the development of new and improved lubrication systems and technologies. By using ILC Lube lubrication systems, companies can enhance the performance and lifespan of their machines, reduce maintenance costs, and increase productivity.

Tailored Lubrication System Advice: We Help You Make the Right Choice

As lubrication specialists, we understand that each type of machine is unique and that operational conditions, such as ambient temperature and location, influence the selection of the most suitable lubrication method. If you need assistance in finding the ideal solution that meets your specific lubrication needs, we are ready to provide you with excellent advice. We offer solutions with an optimal price-performance ratio and would be happy to visit you on-site to provide tailored recommendations. Don’t hesitate to contact us.

Discover Simalube: the perfect solution for automatic single-point lubrication – fully autonomous, operates without any external power source.

For a complete range and expert advice, visit Pomac Lub-Services