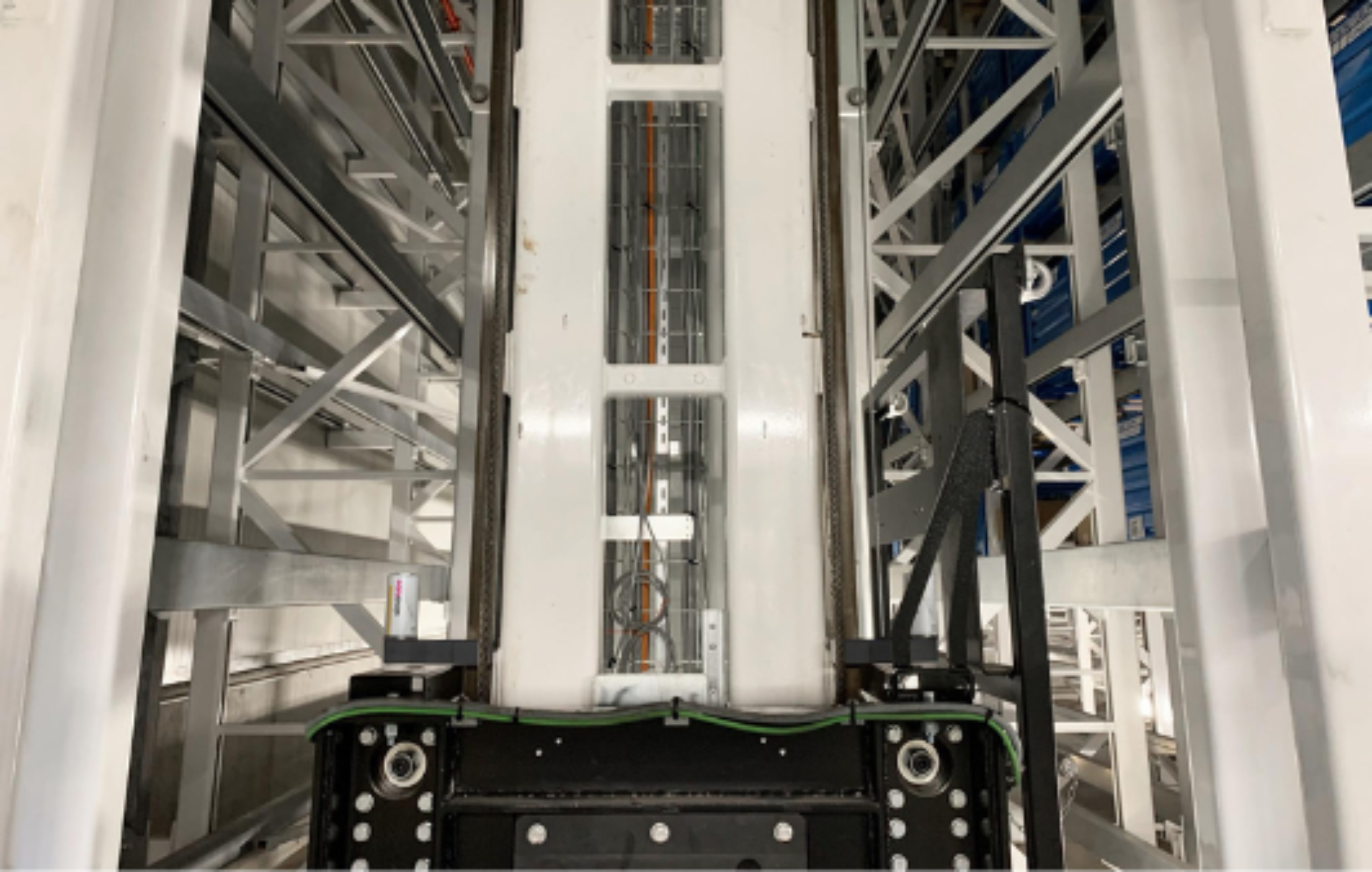

In the fast-moving and demanding world of logistics, efficiency and reliability are the keys to success. High-bay warehouses, conveyor systems, sorting systems and transport vehicles are at the heart of every logistics operation. These ultra-modern systems are in operation around the clock and must be able to withstand the highest loads at all times. One challenge here is the constant and precise lubrication of the numerous lubrication points - a task that is solved reliably and efficiently with the simalube automatic lubricator from simatec.

| Challenges | Solution |

|---|---|

| No contamination of systems and products due to uncontrolled lubricant leakage from excess grease/oil | Simalube grease and oil dispenser to refill yourself |

| No time for maintenance interventions, as the logistics run around the clock | Brush for lubricating chains and guides |

| 100% availability of the systems must be guaranteed | Brush with side connection, for applications in confined spaces |

| Limited space | Simalube lubricant dispenser in a size and running time precisely matched to consumption |

| Small amounts of lubrication / time | The smallest lubricator, Simalube 15 ml, is used where space is limited |

| The use of approved speciality lubricants requires a product that can be used flexibly | Matching accessories from the Simatec product range |

| Minimisation of wear and tear | IMPULSE connect: Digital monitoring and configuration of the lubrication points via Bluetooth®. The lubrication points can be monitored digitally. The device can be used to increase the pressure up to 10 bar. |

Areas of application and advantages

| Simalube applications areas in the logistics industry process | Advantages of automatic lubrication | Simalube applications in logistics |

|---|---|---|

| Conveyor belts/systems | Less system downtime | Bearings |

| Sorting systems | Reduced wear and longer component service life | Slide rails |

| Picking robots | Long-term supply of lubrication points that are difficult to reach | Chains |

| Packaging systems | Increased operational reliability, as manual lubrication is not required | Joints |

| Lifting systems | Less time required for maintenance | Gear racks |

| Transport vehicles | Robotic arms and limbs | |

| Guide rollers |

| Systems/machines in logistics companies | Advantages of simalube lubrication systems |

|---|---|

| Conveyor systems | Reliability: Once installed, the lubrication points are reliably supplied with lubricant and are no longer forgotten |

| Fan systems | Reduction in service and maintenance costs: no need for manual lubrication, which saves an enormous amount of time |

| Gearboxes/engines | Longer system service life thanks to continuous and precise lubrication |

| Palletising systems | No need to switch off the systems during maintenance |

| Blower motors | Available in five sizes: 15, 30, 60, 125 and 250ml, plus multipoint 5x8ml |

| Pumps | Flexibility: The running times of the dispenser are infinitely adjustable from 1–12 months |

| Fans | The progress of the dispensing process can be monitored at any time thanks to the transparent housing (quantity control) |

| Vibrating screens | Installation is possible in the tightest of spaces |

| Cooling units | The hermetically sealed system prevents the ingress of dirt (IP68) |

| Cranes | Simple, ecological disposal (100% recyclable) |

ILC Lube: Supplier of Advanced Lubrication Systems for Various Industries

ILC Lube is a leading manufacturer of lubrication systems and equipment for diverse industries. The company offers a comprehensive range of lubrication systems, including progressive lubrication systems, metering systems, single and multiple metering valves, and manual lubrication systems. ILC Lube is known for its high-quality, custom-made lubrication systems and has built a global reputation for quality, reliability, and durability. Their lubrication systems are used in various industries, including metal, paper, food, automotive, and machine construction.

ILC Lube has a passion for innovation and is constantly working on the development of new and improved lubrication systems and technologies. By using ILC Lube lubrication systems, companies can enhance the performance and lifespan of their machines, reduce maintenance costs, and increase productivity.

Tailored Lubrication System Advice: We Help You Make the Right Choice

As lubrication specialists, we understand that each type of machine is unique and that operational conditions, such as ambient temperature and location, influence the selection of the most suitable lubrication method. If you need assistance in finding the ideal solution that meets your specific lubrication needs, we are ready to provide you with excellent advice. We offer solutions with an optimal price-performance ratio and would be happy to visit you on-site to provide tailored recommendations. Don’t hesitate to contact us.

Discover Simalube: the perfect solution for automatic single-point lubrication – fully autonomous, operates without any external power source.

For a complete range and expert advice, visit Pomac Lub-Services