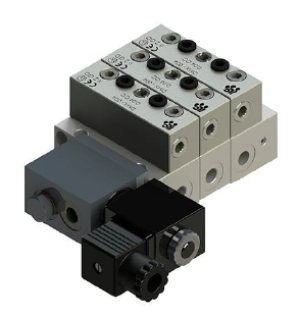

Solenoid valves for DMX progressive distributors: precision and control in lubrication

On this page, you will find solenoid valves for DMX progressive distributors, designed for precise control of lubricants in automatic central lubrication systems. Solenoid valves are a key component of modern lubrication systems as they allow electronic control of oil and grease, ensuring reliable and controlled lubrication.

Operation and application

A DMX solenoid valve opens or closes automatically based on an electrical signal. This allows a precise amount of lubricant to be delivered at the right moment to the dosing elements. This technology makes it possible to efficiently manage both simple and complex lubrication systems with less risk of over- or under-lubrication.

Thanks to the modular design, solenoid valves can be easily integrated into existing DMX systems, making the installation flexible and easily adaptable to changing production requirements.

Technical advantages and benefits

-

Electronic precision: accurate control of lubricant, reducing machine wear.

-

Easy installation: compatible with modular DMX progressive distributors and easy to install without complex modifications.

-

Reliability: designed for long-term use in industrial environments with minimal risk of failure.

-

Flexibility: suitable for both oil and grease, applicable in various industrial sectors such as metalworking, machine building, and transport.

When to choose DMX solenoid valves?

Solenoid valves are ideal when you want full electronic control of lubrication and require a reliable, reproducible distribution of lubricant. They are often used in complex installations where manual operation or conventional valves provide insufficient control.

ILC Lube: Supplier of Advanced Lubrication Systems for Various Industries

ILC Lube is a leading manufacturer of lubrication systems and equipment for diverse industries. The company offers a comprehensive range of lubrication systems, including progressive lubrication systems, metering systems, single and multiple metering valves, and manual lubrication systems. ILC Lube is known for its high-quality, custom-made lubrication systems and has built a global reputation for quality, reliability, and durability. Their lubrication systems are used in various industries, including metal, paper, food, automotive, and machine construction.

ILC Lube has a passion for innovation and is constantly working on the development of new and improved lubrication systems and technologies. By using ILC Lube lubrication systems, companies can enhance the performance and lifespan of their machines, reduce maintenance costs, and increase productivity.

Tailored Lubrication System Advice: We Help You Make the Right Choice

As lubrication specialists, we understand that each type of machine is unique and that operational conditions, such as ambient temperature and location, influence the selection of the most suitable lubrication method. If you need assistance in finding the ideal solution that meets your specific lubrication needs, we are ready to provide you with excellent advice. We offer solutions with an optimal price-performance ratio and would be happy to visit you on-site to provide tailored recommendations. Don’t hesitate to contact us.

Discover Simalube: the perfect solution for automatic single-point lubrication – fully autonomous, operates without any external power source.

For a complete range and expert advice, visit Pomac Lub-Services