24 products found

Metering valves components

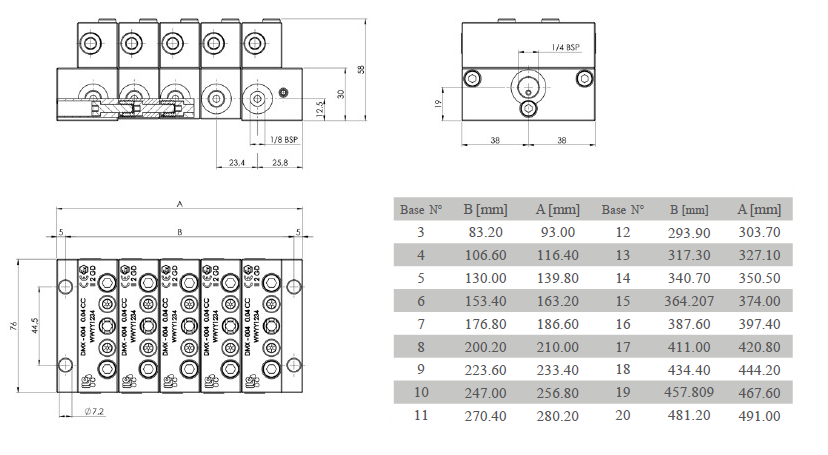

The minimum number of metering valves in an as- sembled block is 3 and the maximum is 20.

The installation on the base is made using the two fixing screws TEC-UNI-5931 UNF 1/4 “x 1” 1/4 sup- plied with the metering valve.

The number of required metering elements, as long as their output and the presence of a monitoring control sensor, are mandatory in order to choose the right model.

It’s always possible to replace a valve with a diffe- rent model without disconnecting the tubelines or open the base.

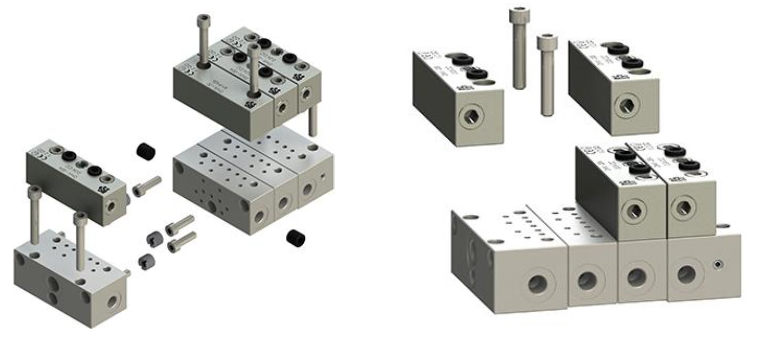

Assembly

Assembling dosing elements is extremely simple.

Place it on its own base. Insert fixing screws and tighten them using a maximum 12 nm force.

During the operation pay attention to “O”-ring on the support base side.

Replacement

The same operation is required to replace a valve of insertion of a by-pass element.

Remove the fixing screws and the element itself. Install the new element as in the image aside.

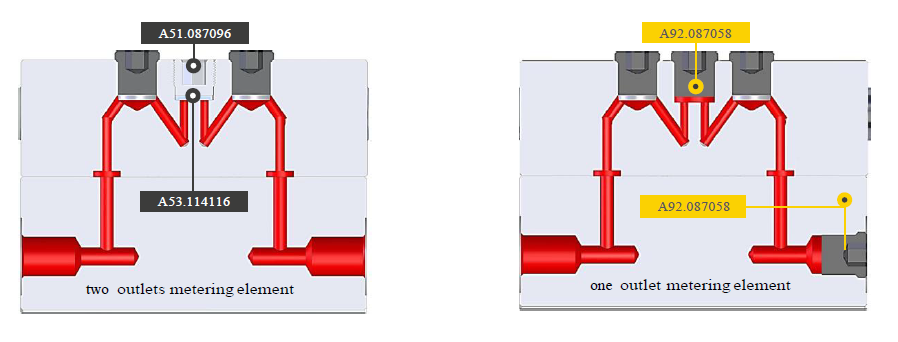

Outlets

Metering elements are supplied with a set-up for one or two separate outputs.

It is always possible to modify this condition (from one to two and vice versa) turning the adapter screw between the vertical outputs as explained in the image below.

BE CAREFUL! Always shut a no-longer-required outlet as shown in the image below. Else you would occur in system block and a valve alarm.

It is possible to sum the two output of the same element. Remove the grub screw (code A51.087096 1/8” K) and the ring (Code A53.114116) replacing it with the grub screw (code A92.087058 1/8” K) as shown in the image below.

When the two outlet are connected remember to shut the unused one using the grub screw (code A92.087058 1/8” BSP CIL).

Assembly block dimensions

ILC Lube: Supplier of Advanced Lubrication Systems for Various Industries

ILC Lube is a leading manufacturer of lubrication systems and equipment for diverse industries. The company offers a comprehensive range of lubrication systems, including progressive lubrication systems, metering systems, single and multiple metering valves, and manual lubrication systems. ILC Lube is known for its high-quality, custom-made lubrication systems and has built a global reputation for quality, reliability, and durability. Their lubrication systems are used in various industries, including metal, paper, food, automotive, and machine construction.

ILC Lube has a passion for innovation and is constantly working on the development of new and improved lubrication systems and technologies. By using ILC Lube lubrication systems, companies can enhance the performance and lifespan of their machines, reduce maintenance costs, and increase productivity.

Tailored Lubrication System Advice: We Help You Make the Right Choice

As lubrication specialists, we understand that each type of machine is unique and that operational conditions, such as ambient temperature and location, influence the selection of the most suitable lubrication method. If you need assistance in finding the ideal solution that meets your specific lubrication needs, we are ready to provide you with excellent advice. We offer solutions with an optimal price-performance ratio and would be happy to visit you on-site to provide tailored recommendations. Don’t hesitate to contact us.

Discover Simalube: the perfect solution for automatic single-point lubrication – fully autonomous, operates without any external power source.

For a complete range and expert advice, visit Pomac Lub-Services