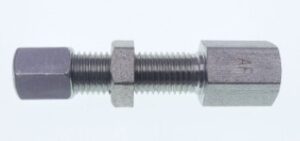

Cutting Ring Fittings 24° DIN 2353 / ISO 8434-1

Cutting ring fittings are essential for securely connecting tubes, hoses, and piping systems when pumping grease or oil. They provide excellent sealing and mechanical strength.

5 producten gevonden

Where can this bulkhead fitting be used?

This special 24° bulkhead screw connection with a greasing aid function is a perfect fitting to supply lubrication points which are difficult to reach. When the lube points and bearings are located behind protective covers and sheets, our bulkhead fitting with a grease nipple is a slim solution for manual and supplementary lubrication as well as emergency lubrication.

When for some technical circumstances the greasing block solution is too bulky and too oversized, a slim and elegant solution is required. Our bulkheads with grease nipple connection are the ideal solution here.

Some more information? Please contact our technicians for a technical support !

You can find suitable grease nipples for our bulkhead fittings by clicking on the image. Available in straight, 90° and 45° versions.

What are the mounting options?

If a lubrication line has to be routed through a protective wall or a cover plate in a lubrication system, the following mounting variants are possible:

This type of bulkhead fitting is equipped with a 24° cutting ring connection according to DIN 2353 / ISO 8434-1 on one side. Here it is possible to mount a hose stud, screw sleeve and a high pressure hose 840 bar. This line is further led to the greasing point. Here at the bearing side, either a cutting ring fitting is used again or a push-in fitting and a hose stud with a claw groove. A plastic tube can also be used as a grease line.

On the other side of this straight bulkhead fitting, an internal thread allows a direct mounting of a grease nipple and is supplied with a standard hand lever grease gun.

ILC Lube: Supplier of Advanced Lubrication Systems for Various Industries

ILC Lube is a leading manufacturer of lubrication systems and equipment for diverse industries. The company offers a comprehensive range of lubrication systems, including progressive lubrication systems, metering systems, single and multiple metering valves, and manual lubrication systems. ILC Lube is known for its high-quality, custom-made lubrication systems and has built a global reputation for quality, reliability, and durability. Their lubrication systems are used in various industries, including metal, paper, food, automotive, and machine construction.

ILC Lube has a passion for innovation and is constantly working on the development of new and improved lubrication systems and technologies. By using ILC Lube lubrication systems, companies can enhance the performance and lifespan of their machines, reduce maintenance costs, and increase productivity.

Tailored Lubrication System Advice: We Help You Make the Right Choice

As lubrication specialists, we understand that each type of machine is unique and that operational conditions, such as ambient temperature and location, influence the selection of the most suitable lubrication method. If you need assistance in finding the ideal solution that meets your specific lubrication needs, we are ready to provide you with excellent advice. We offer solutions with an optimal price-performance ratio and would be happy to visit you on-site to provide tailored recommendations. Don’t hesitate to contact us.