Specifications

| Code | 81-O2-CE-24V |

| Lubricant | Oil |

| Reservoir capacity | 2L |

| Timer | Without timer |

| Power supply voltage | 24 V DC |

| Capacities measured | 200cc/1' 24 V DC |

| Outlet connections | 2 BSP 1/4” seats (standard supplied with 1 left-hand lock cap) |

| Electrical connections | 1 cable gland for power supply ; 1 cable gland for signals |

| Filling | Cap with 200 μ load filter |

| Pressure gauge | 0 - 60 bar |

| Operation pressure | 24 bar |

| Lubricant specification | Oils 50 to 1000 cSt |

| Operating temperature | 0°C - 50°C |

| Protection rating | IP-54 |

| Weight (reservoir empty) | 3.5 kg |

Electric pump without internal timer

The pump is activated and controlled by the machine’s PLC.

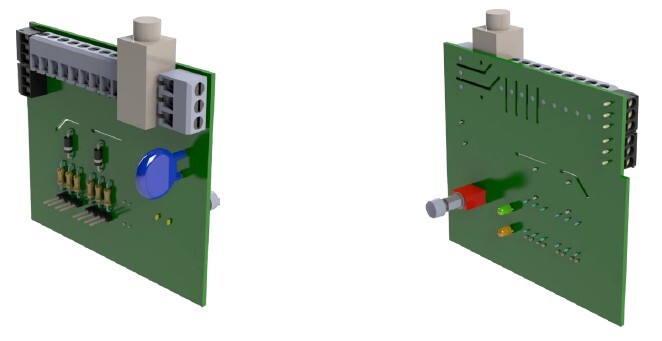

It is supplied with a push button for possible intermediate lubricating operations, power LED and pump working LED.

It also has a pressure switch for lubricant pressure control, an electric low level sensor (open when the reservoir is empty) and a pressure gauge.

The power LED (GREEN) and the operating LED (YELLOW) are on the front panel.

DC motor

- Rated voltage: 24 V DC

- Rated power: 60W

- Rated current: 3 A

- Operating mode according to DIN EN 60034 - 1: S3,20%

- Internal fuse: 6.3 A

Pressure switch

- Output signal: open with no pressure (NO)

- Calibration pressure: 22 bar

- Actuating voltage: less then 250 V AC

- Maximum switchable current: 0,5 A

Reed Sensor (Low oil level)

- Ouput Signal: NO

- Switching voltage: < 250 V AC

- Switching current: 1 A max

- Rated power: 40 W

- Max. temperature: 80° C

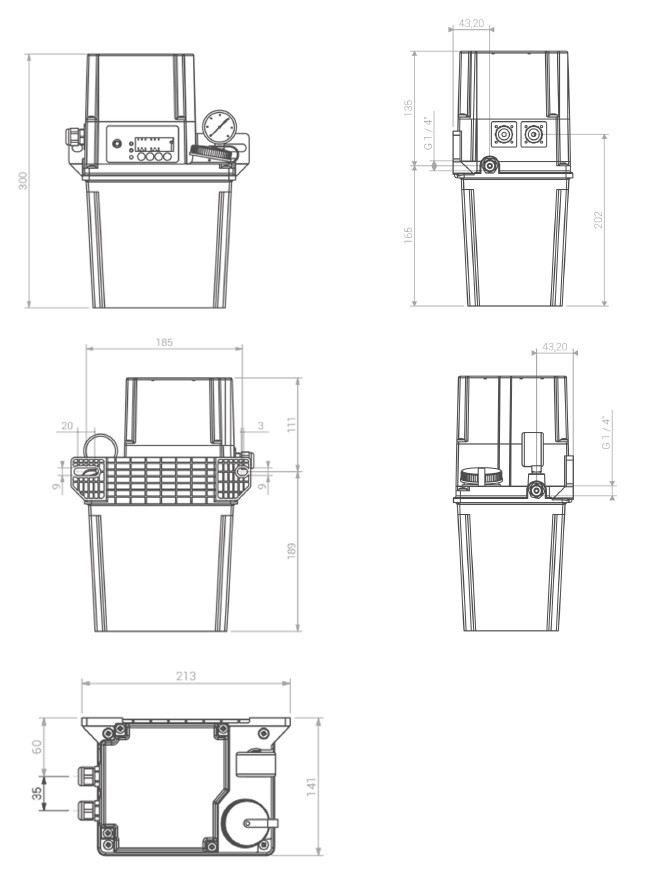

Dimensions

ILC Lube: Supplier of Advanced Lubrication Systems for Various Industries

ILC Lube is a leading manufacturer of lubrication systems and equipment for diverse industries. The company offers a comprehensive range of lubrication systems, including progressive lubrication systems, metering systems, single and multiple metering valves, and manual lubrication systems. ILC Lube is known for its high-quality, custom-made lubrication systems and has built a global reputation for quality, reliability, and durability. Their lubrication systems are used in various industries, including metal, paper, food, automotive, and machine construction.

ILC Lube has a passion for innovation and is constantly working on the development of new and improved lubrication systems and technologies. By using ILC Lube lubrication systems, companies can enhance the performance and lifespan of their machines, reduce maintenance costs, and increase productivity.

Tailored Lubrication System Advice: We Help You Make the Right Choice

As lubrication specialists, we understand that each type of machine is unique and that operational conditions, such as ambient temperature and location, influence the selection of the most suitable lubrication method. If you need assistance in finding the ideal solution that meets your specific lubrication needs, we are ready to provide you with excellent advice. We offer solutions with an optimal price-performance ratio and would be happy to visit you on-site to provide tailored recommendations. Don’t hesitate to contact us.

Discover Simalube: the perfect solution for automatic single-point lubrication – fully autonomous, operates without any external power source.

For a complete range and expert advice, visit Pomac Lub-Services