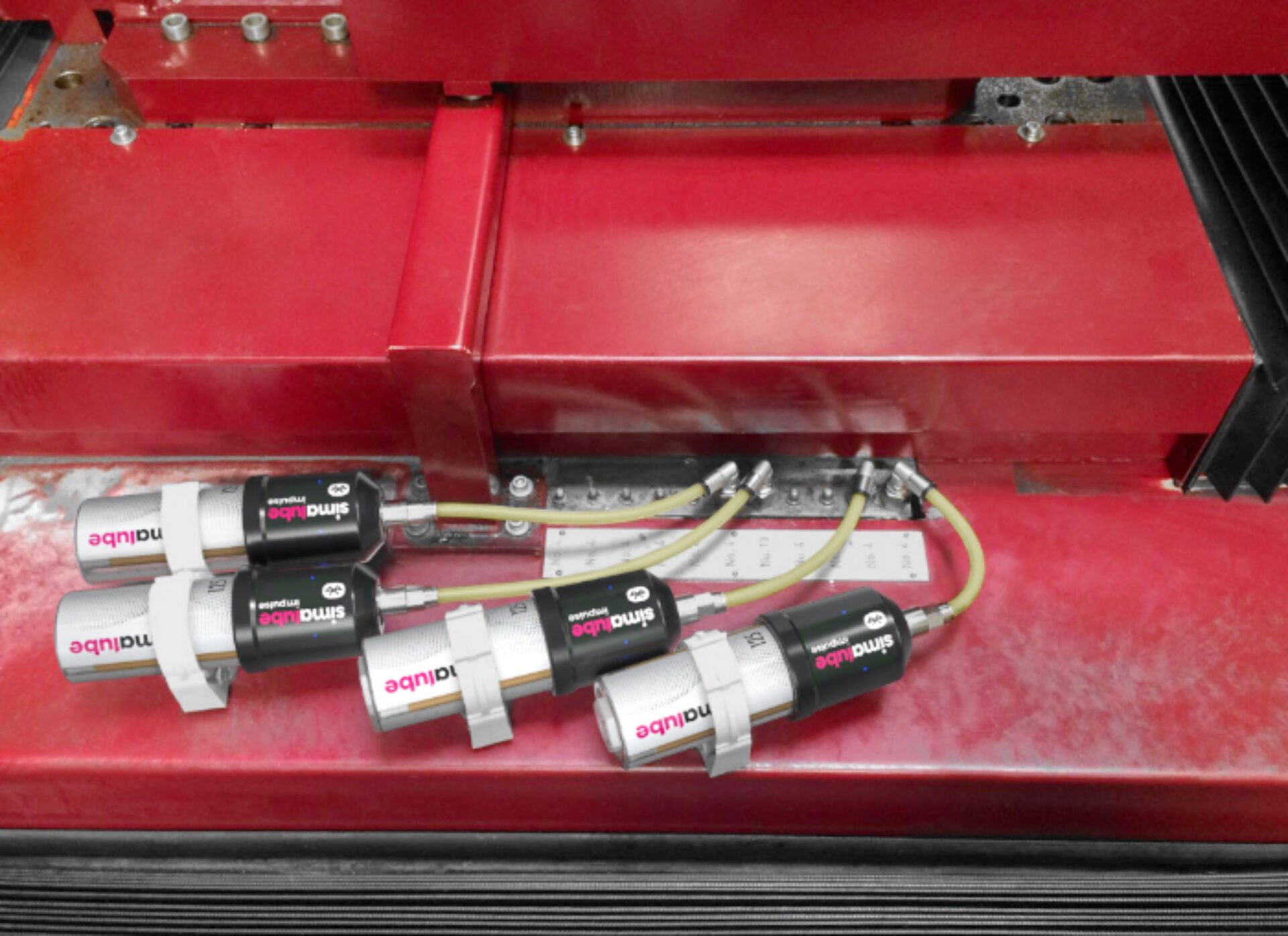

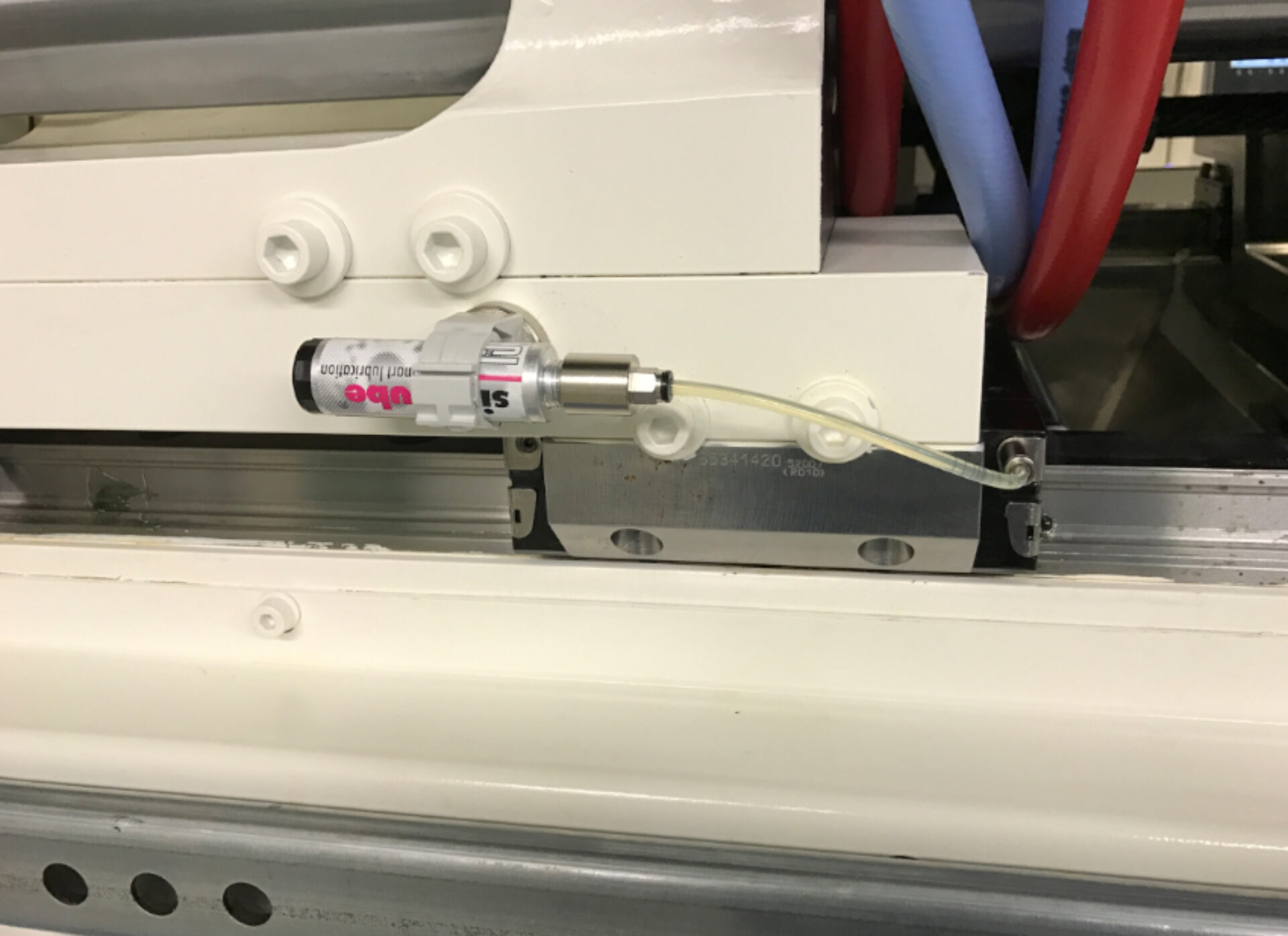

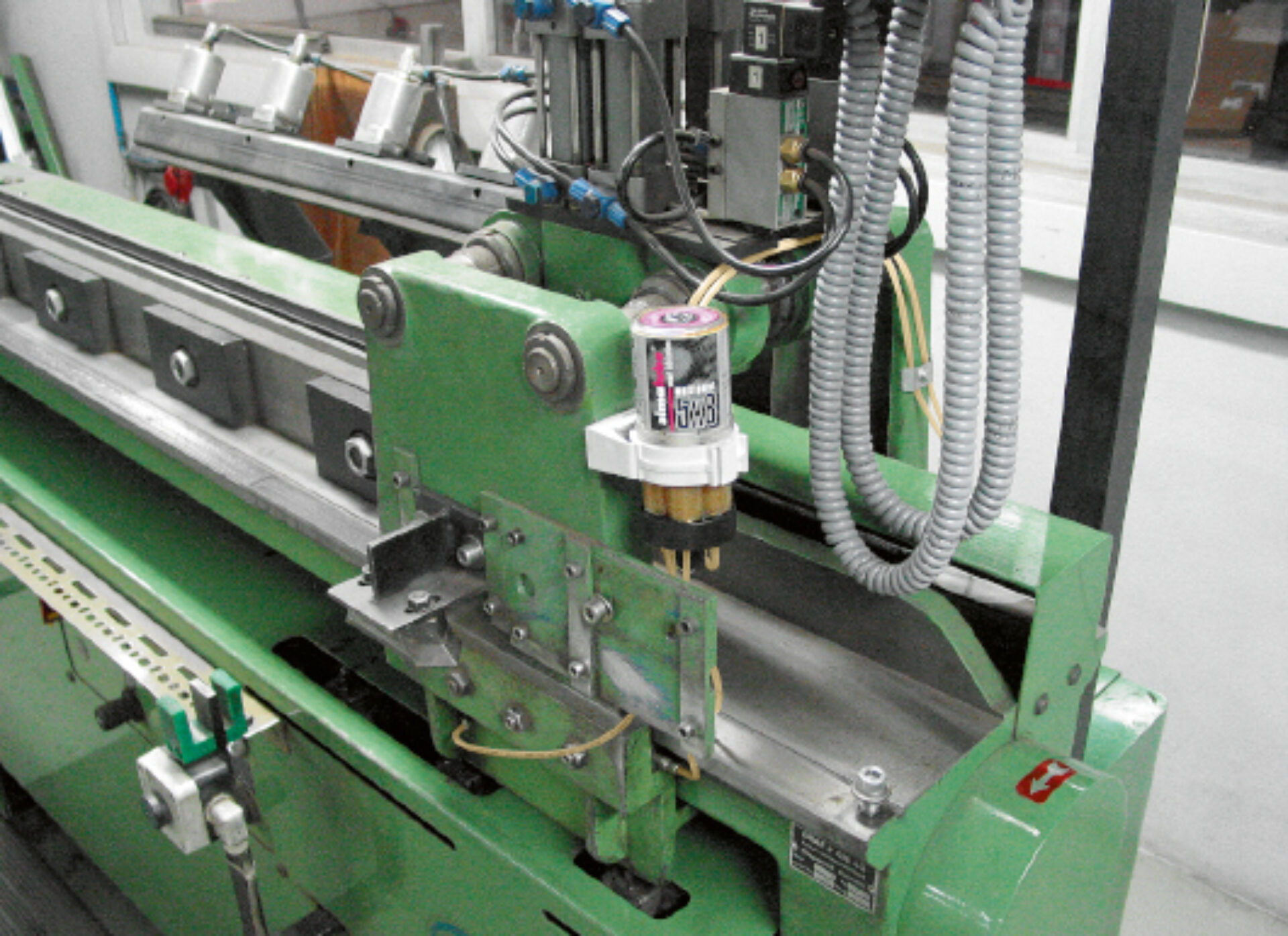

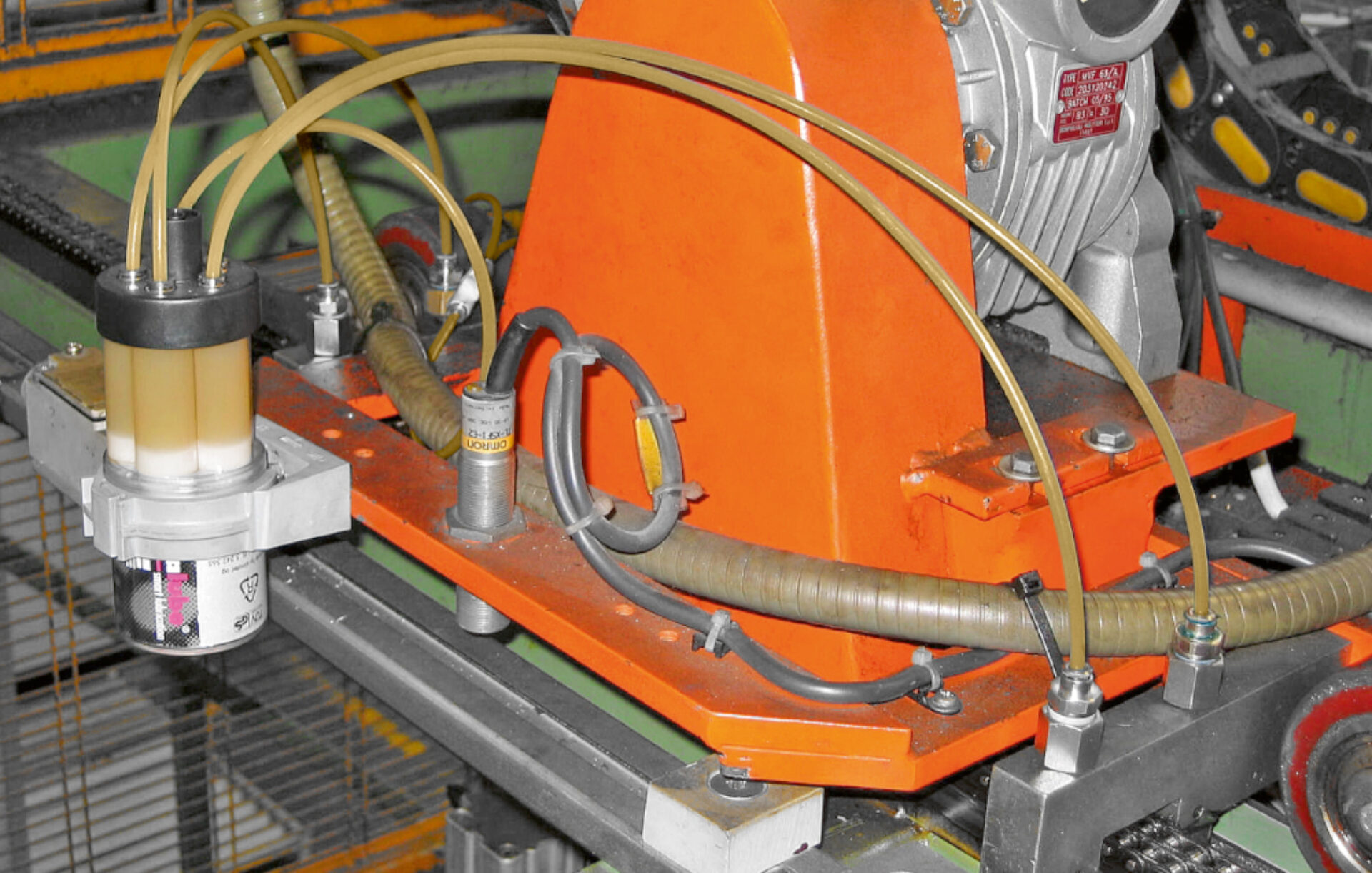

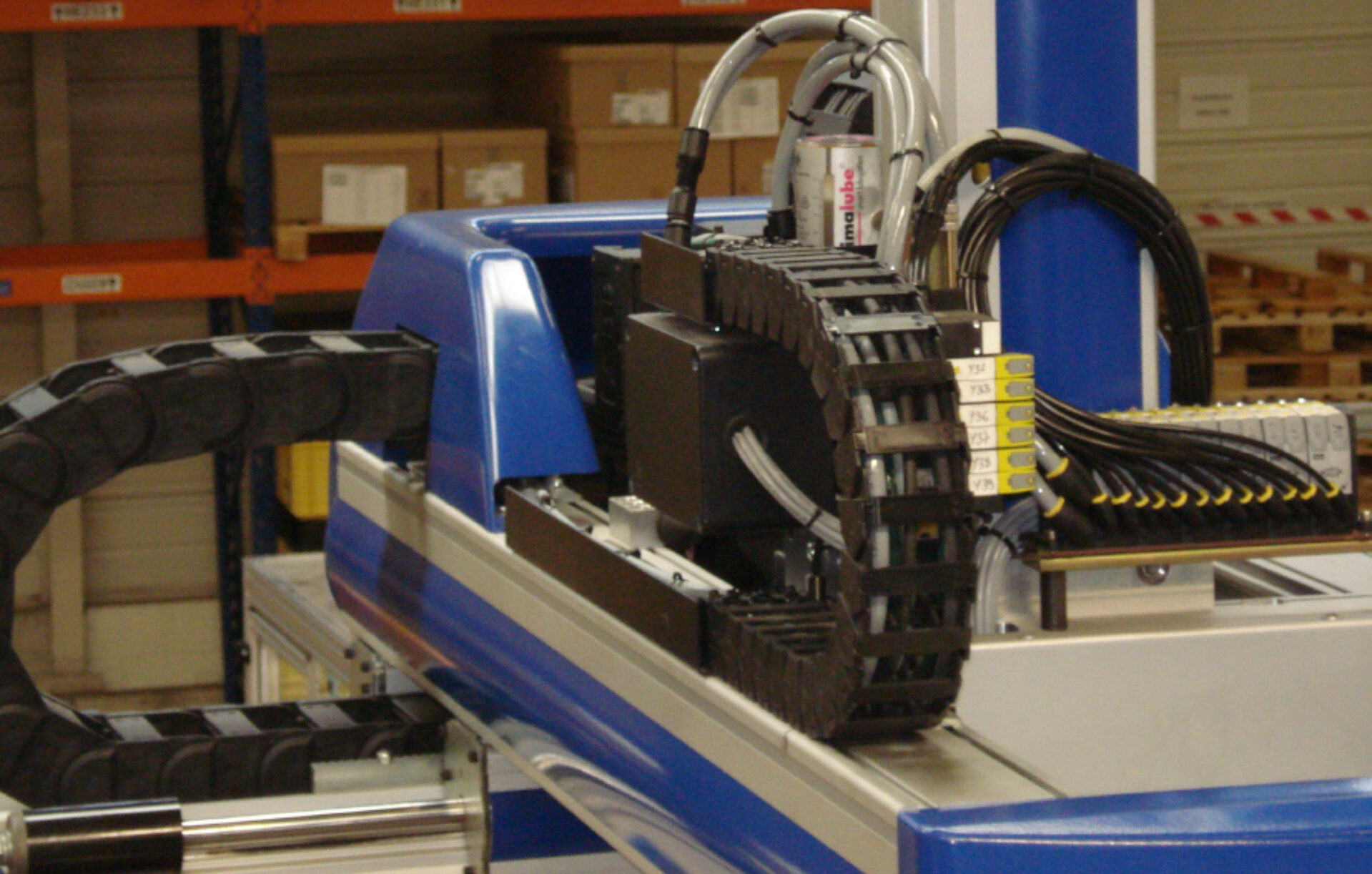

Nowadays, more and more production processes run partly or fully automatically to save costs, increase efficiency and improve the safety of personnel. Automatic and permanent lubrication is essential to ensure that these processes run as smoothly and steadily as possible. With the simalube lubricators, the lubrication process is automated and also increases machine efficiency. This results in lower costs and ultimately more profit.

Areas of application and advantages

| Benefits of the Simalube lubrication system | Typical installations | Typical applications |

|---|---|---|

| Reliable lubrication with low maintenance requirements | Robots | Bearings |

| Minimal wear of components and thus reduction of maintenance costs | Cranes | Chains |

| No unplanned downtimes, production interruptions of the plants | Palletizing systems | Guides |

| Forklifts | Gears | |

| Conveyor tracks | Other mechanical parts |

| Challenges | Solutions |

|---|---|

| No contamination of the systems by excess grease | Simalube lubricators in the size and runtime precisely matched to consumption |

| Limited space | In tight spaces, the smallest dispenser, Simalube 15 ml, is used |

| Small amounts of lubrication / time | Matching accessories from the Simatec product range |

| Simalube IMPULSE connect for easy monitoring and management of lubrication points |

That's why you choose ILCLUBE.

Over 5.000 products in stock

Wide range: we offer a complete concept!

Fast delivery time: 1 to 2 working days

Personalized service